Contents

- Process for an integrated pest management strategic plan

- 2022 IPMSP for brassicas working group members

- IPM critical needs by category

- Brassica production in Oregon and Washington: an overview

- IPM utilization in brassica crops in northwestern Oregon and southwestern Washington

- IPM strategies used by most brassica growers

- The PAMS approach

- Invertebrate pests and IPM methods reported by brassica growers

- Weeds and IPM methods reported by brassica growers

- Pathogens and IPM methods reported by brassica growers

- Vertebrate pests and IPM methods reported by brassica growers

- Appendix: Using PAMS terminology

Process for an integrated pest management strategic plan

This publication identifies pest management priorities and recommends increased adoption and implementation of integrated pest management for fresh market brassica crop production in northwest Oregon and southwest Washington. Growers, commodity-group representatives, pest-control advisors, university specialists, and other technical experts from the region’s vegetable production industry contributed to the content of this strategic plan. The lead organizers contacted members of this group on December 2021 and January 2022 to ask about brassica production practices, challenges, successes and concerns. The group met in Wilsonville, Oregon, on Jan. 19, 2023, to clarify information, review its accuracy and identify further IPM critical needs. This plan outlines major pests, current IPM practices and critical needs for research, education, and regulation for brassica production in western Oregon and Washington. Additional Pest Management Strategic Plans, including reports from other states and agricultural industries, are in the National IPM Database.

This strategic plan begins with IPM critical needs. These lists are based on interviews and an online survey sent to working group participants on June 4, 2022. Items are ranked according to the results of the online survey following the working group meeting on Jan. 19, 2023.

This publication includes an overview of fresh market brassica production in Oregon and Washington. The rest of the document is an overview of management practices and challenges, organized by pest type, to help understand whole-season management practices and constraints. We identify key pests and provide links about pest biology and management recommendations. We present the working group’s current management practices as a “Prevention, Avoidance, Monitoring, and Suppression” framework. This approach places practices within a simple IPM classification and demonstrates where additional tools or practices may be needed. For more information, see “PAMS Framework” from OSU Extension: https://extension.oregonstate.edu/pests-weeds-diseases/ipm/pams-framework (Appendix I).

IPM critical needs by category

The items in this section come from responses, suggestions and comments made during interviews conducted between December 2021 and January 2022 with volunteer participants from our working group of farmers and crop consultants. Participants were asked about the most urgent needs for their farm operations, clients and their industry related to IPM. The responses were classified into education, research or regulation. Responses were further classified into general pathogens, weeds, vertebrates or other. An online survey emailed on June 4, 2022, allowed participants to prioritize items. The survey was closed on June 30, 2022.

In the survey, participants ranked suggestions as top priority or most important (value of 3), medium importance (value of 2), and least importance (value of 1). The lists below are in order of mean values (1–3) after voting by survey participants (n = 14 participants), starting with the highest average score.

Survey participants could suggest new topics while completing the survey and during the final working group meeting. These suggestions are listed as “other” or noted as “unranked” in their respective category. They were not ranked as part of the survey. There have only been minor edits for spelling or clarity.

Research: general

- Efficacy of biological control agents in brassicas.

- Implementation of biological controls with spray programs.

- Efficacy and timing of irrigation methods (for example, overhead versus drip) for IPM in brassicas (for example, how it affects pathogen cycles and insect pest cycles).

- Pesticide products compatible with IPM practices (currently too few).

- Understanding ecological mechanisms of biological control in brassicas.

- Efficacy of targeted or “softer” chemistries.

- Real-time nitrogen testing on the farm (for example, test today to plant tomorrow).

- Research into additional organically compatible pesticides and products.

- Research into biochar as an amendment.

- Integrated pest management of rodents, including voles.

- Research into insect frass as a fertilizer or soil health improvement.

- Health effects and nutritional content of brassicas produced through organic versus conventional methods, including public perception.

- Effective methods of interplanting.

- Integrated pest management of geese.

Research: pathogens

- Management of downy mildew, including scouting, spray timing and what products to use.

- Increase infrastructure and resources for crop consultants to recognize and diagnose diseases.

- Nonchemical-based club root management (for example, cultural practices such as rotation, soil health and moisture management).

- Efficacy of liming to prevent club root.

- Management of root rots.

- Management of emerging pathogens in case they become established.

- Management of soft rots.

- Cyazofamid (fungicide) on club root in turnip and rutabaga (unranked).

- Chemical controls of club root in brassicas (unranked).

Research: weeds

- New herbicidal chemistries or products that can be applied during crop development.

- In-row weed management solution for direct-seeded crops.

- Automated weed solutions: “smart” cultivation tools that are better than a piece of steel on a tractor.

- More organic herbicide chemistries.

- Weed management for weeds affecting brassica production in Central and Eastern Oregon only.

- More research into practices for direct-seeding in dense beds so the crop can shade out weeds.

Research: invertebrates

- Management of aphids, including scouting, effective products or methods, and spray timing.

- Long-term management of the diamondback moth.

- Management of flea beetles in organic and conventional systems.

- General management of root maggot — chemical and nonchemical methods.

- Resistance of diamondback moth to current chemistries.

- Efficacy of organic insecticide chemistries.

- Biological control of specific pests: which natural enemies are effective against which pests?

- Resistance of aphids to current chemistries.

- New or updated management of symphylans.

- Management of slugs (beyond Sluggo and mowing).

- Metrics on measuring the efficacy of biological control.

- Efficacy of nematodes as biocontrol agents.

- Management of beet leafhopper.

- Management of cabbage whitefly in organic systems.

- In general, soil-dwelling insects (including symphylan) control (unranked).

Regulatory: general

- Add more brassicas crops to current chemistry labels (some effective products cannot be used in brassicas).

- Increased understanding by regulatory bodies of the effects of restricting or removing chemistries before alternatives exist.

- Revise deer-hunting regulations with consideration for deer effects on agriculture.

- Regulatory agencies, such as the Environmental Protection Agency and the Oregon Department of Agriculture, should improve communication with growers, including consideration of concerns of growers earlier in the regulatory process.

- Effective products labeled for downy mildew control in brassicas.

- Seed testing for more pathogens.

- Revise organic standards for nutritional inputs (currently require proof of deficiency, which does not work with production practices).

- Increased access to land for young farmers.

- Revise organic standards to balance international competition with domestic production.

- Loosening of work restrictions to allow for apprenticeships on farms.

- Simplification of pesticide labels, especially for finding preharvest intervals and restricted entry intervals.

- Enforcement of land-use reporting to publicly leased lands.

- Organic and regenerative mandates for publicly owned leased land.

Regulatory: other (unranked)

- Labor, loss of chemistries.

- The state regulates hemp and marijuana separately from general agriculture. Stopping sales of chemistries for all crops over the last few years because of hemp and marijuana testing is an overreach by the Oregon Department of Agriculture.

Education and outreach: general

- Materials on the relationships between pests and diseases in brassicas crops.

- Resources with accurate information on soil health improvement.

- Create an IPM handbook for brassicas in the Pacific Northwest.

- General toolkit for disease management, including identification aids and decision-management tools.

- Educational materials for vegetable production specific to our region, including production methods and nutrition.

- Identification aids of brassica pests, including printed (nondigital) publications and handouts.

- More information about IPM implementation for large farms, including planting for beneficials, which crops and which pests.

- Increase awareness of VegNet (Oregon State University-based pest monitoring resource).

- Increased farm visits from Extension agents.

- Additional efficacy data on products listed in the Pacific Northwest Handbooks.

- IPM classes and workshops exploring case studies, challenges and successes, especially for new growers.

- Increase awareness of USPest.org and other Oregon IPM platforms.

- More local workshops for vegetable growers (30 minutes or less travel time).

- Materials on implementing rotations in brassicas crops: what are they, why are they needed and how do you do it.

- Materials produced in multiple languages, with consideration for regional dialects (for example, Salvadoran and Guatemalan).

Education: other

- Increase distance disease and insect diagnoses to help growers reduce the time between identification and implementing control measures.

Brassica production in Oregon and Washington: an overview

Brassica production and references to brassicas in this document include the production of crops in the family Brassicaceae for fresh markets. This includes broccoli, cauliflower, cabbage, napa cabbage, bok choy, kale, kohlrabi, radish, rutabaga and turnips. This project did not consider brassicas for the processed market, specialty crop seed production, cover crop production or oilseed crop production. Many growers produce these and other vegetables or crops not in this family for multiple markets. This project focused on a narrower scope of production for an initial integrated pest management strategic plan for this industry, limited only to the types of brassica crops listed above. Report authors recommend broadening future IPMSPs to include related production areas of the fresh market vegetable industry to address sectors that were not covered for this project but likely have similar needs or pest problems.

For the most recent data on acreages and numbers of farms producing brassicas for fresh market and processed production in Oregon and Washington, see the 2017 Census of Agriculture: Oregon and 2017 Census of Agriculture: WA, USDA National Agricultural Statistical Service.

Integrated pest management utilization in brassica crops in northwestern Oregon and southwestern Washington

Brassica vegetable production in northwestern Oregon and southwestern Washington represents a diverse set of growers and crops. That diversity feeds into the complexity of managing the pest and disease problems in brassica crops.

On one side, there are growers who typically produce fewer types of brassica vegetables and whose fields tend to be more than 40 acres. These larger fields often produce crops for vegetable-processing companies, but some fresh market producers in the region operate farms of this size. Larger-acreage growers typically have ready access to private crop advisors and an array of conventional pesticides.

On the other side, there are growers who produce many cruciferous vegetables on less than 1 acre throughout the year for fresh markets. Participants classified as having organic production (n=8) had acreages between 12 and 200 acres of brassicas versus conventional producers (n=3) who had farms of up to 400 acres used for brassica production.

Factors influencing pest management decision-making include products grown, acreage, markets (for example, grocery stores, restaurants and community-supported agriculture operations) and geographic location. Organic and conventional brassicas producers in northwestern Oregon and southwestern Washington approach pest management differently. Both types of producers felt pressure from insects, weeds, pathogens and vertebrates. The options available to organic versus conventional growers differed and seemed to influence pest management tactics.

Organic production

Organic producers identified a wider variety of markets for their products, including community-supported agriculture and direct marketing to restaurants, co-op groceries and larger grocery chains. Participating conventional growers sold to larger grocery chains and reported a high risk of rejection of larger loads due to insect and pathogen damage. This suggests that the pressure to grow undamaged produce may be less flexible for larger-scale producers; the customer base for smaller-scale, organically produced vegetables may be more tolerant of insect or pathogen damage. For example, some participating growers indicated that CSA customers tolerated holes in leaves on greens if the customers knew that conventional pesticides were not used on the crops.

Some small-scale producers focus less on improving the yield from their acreage and more on profitability. That means finding customers who pay a higher price for produce grown without synthetic pesticide inputs and are more accepting of cosmetic damage. In restaurants, kitchen prep staff can remove damaged edges of kales and cabbages. At grocery stores, damage spotted during inspection would be rejected because shoppers would leave the product on the shelf. This type of product rejection increases labor costs for conventional brassica crops to reinspect a rejected load.

Organic growers implemented multiple alternatives to pesticides. They used exclusion techniques, such as polyester row cover (Reemay, for example) early in the season, mechanically removed damaged or infested leaves from leafy crops and created and maintained habitat for natural enemies. They also hand-removed weeds during the production season and frequently scouted to catch pests early. There are few options for organic sprays to control insect pests. More than one grower reported that as they transitioned acreage to organic production and implemented more IPM strategies, they found less need for pesticide applications. At least one grower reported that they manage pests by improving plant health, excluding pests and employing natural enemies. Most pest managers in our working group applied chemical pyrethrins or spinosad to defeat brassicas pests. Growers frequently use azadirachtin or neem oil and practice crop rotation for key pests like cabbage root maggots.

Conventional production

Conventional growers in the IPMSP used some alternative strategies, too, but depended more on pesticide products registered for conventional brassicas production. Growers primarily used insecticides for insect pests and pre-emergent herbicides for weed management. But conventional growers said there are few options that are not phytotoxic to brassica crops or labeled for brassicas use.

Small farms do not have ready access to private crop consultants or the resources to submit plant samples for plant clinic diagnosis. As a result, these growers lack the expertise to name specific diseases occurring in their small farm’s cruciferous crops. Growers following certified organic practices depend on cultural control practices.

Both conventional and organic brassica growers said weed and pathogen pressure leave few IPM-based options. Organic and conventional growers repeatedly said they lack weed management options other than mechanical removal following planting. While there are chemical-application options for brassicas pathogen control, there is insubstantial infrastructure in place for rapid, accurate, affordable or convenient identification of key pathogens. However, organic and conventional growers employ IPM-based strategies where possible.

Brassica production cycle

The following production schedule outlines a brassica cropping cycle. Growing schedules vary according to production methods and the types of brassica plants. Some growers plant multiple crops a season for winter and spring harvest. Many growers rotate crops to disrupt brassica pest and pathogen cycles. For example, they plant a crop of potatoes for a cycle if symphylans are detected.

| Stage | Production activities | Direct management activities (conventional and organic) |

|---|---|---|

| Preplant | Plant seeds in a greenhouse or hoop house for transplant production. Pre-emergent applications of herbicides for weeds | Pre-emergent applications of herbicides for weeds; rotate crops in vulnerable areas (history of pest pressure); flame weeds; disc or mulch weeds or cover crops (green manure); apply fertilizers to support plant health and increase a plant’s resilience against insect damage; monitor and manage soil pH |

| Planting | Transplant starts (for example, collards, kale, braising greens, cabbage)Direct-seed (for example, broccoli, rutabaga, turnip and radish) | Manage weeds that outcompete seedlings; put on row covers such as Reemay or insect-netting; apply pesticide sprays or drenches to transplant trays ahead of planting; use adequate plant spacing to reduce disease-conducive conditions; use larger transplants more tolerant of damage to outcompete weeds; apply fungicides to prevent disease establishment |

| Crop growth | Plant growth and development | Scout for pest issues: first two weeks are critical to stay ahead of issues; spot-spray pesticides for flea beetles and aphids; remove infested plants; monitor irrigation to keep the canopy dry and limit conditions conducive to foliar disease; remove weeds by hand |

| Harvest | Harvest and processing of products | Scout for insect pests (aphids, armyworms, diamondback moth) and damage during harvest; spot pick and remove damaged leaves or aphid-infested leaves or heads; plant cover crops for soil health, weed suppression and bed preparation for the next season or planting |

IPM strategies used by most brassica growers

Integrated pest management was formalized in the 1960s. IPM seeks to control pests (arthropod pests, diseases, weeds, nematodes and vertebrate pests) using multiple complementary tactics in an environmentally and economically sound manner. Tools such as monitoring, sampling, scouting, use of pest or pathogen predictive models, biological control, physical control, cultural control practices, sanitation, use of host plant resistance and chemical control methods are part of the IPM toolbox used by brassica growers and crop advisors in the Pacific Northwest. The goal is to keep the spectrum of pests below economic thresholds for yield impacts, using a selection of these tools harmonized with the control of other pests using production practices.

The tables below list pesticides used or recommended by the brassica working group growers and consultants. The table does not include all products registered for brassica production in Oregon and Washington. Trade names are examples of the products used. This document does not endorse or recommend any products, manufacturers or distributors. Always follow the label instructions when applying pesticides. Some pesticides require an applicator’s license or other certification for use. Always follow state or local pesticide guidelines.

| Insecticides | ||||

|---|---|---|---|---|

| Active ingredient | Products in use (trade name) | Insecticide Resistance Action Committee Group | OMRI listed for organic use | Target pests (reported use) |

| Afidopyropen | Versys, Sefina | 9D | N | aphids |

| Bifenthrin | Capture LFR, Brigade | 3A | N | cabbage root maggot, flea beetle, lepidopterans, seed corn maggot |

| Carbaryl | Sevin | 1A | N | flea beetle |

| Chlorantraniliprole | Caragen, rynaxypyr | 28 | N | lepidopterans |

| Cyantraniliprole | Verimark, Exirel | 28 | N | aphids, cabbage root maggot, lepidopterans, seed corn maggot |

| Flonicamid | Beleaf | 29 | N | mollusks |

| Imidacloprid | Admire | 4A | N | aphids |

| Indoxacarb | Avaunt | 22 | N | lepidopterans |

| Metaldehyde | Deadline | none | N | slugs, snails |

| Methomyl | Lannate | 1A | N | thrips |

| Spinetoram | Radiant | 5 | N | lepidopterans |

| Thiamethoxam | Platinum, Actara | 4A | N | aphids, flea beetle, symphylans |

| Zeta-cypermethrin | Mustang | 3A | N | cabbage root maggot, flea beetle, lepidopterans |

| Azadirachtin / neem oil | none | Y | aphids, flea beetle | |

| Bacillus thuringiensis ssp. kurstaki (BtK) | Leprotec, DiPel | none | Y | lepidopterans |

| Beauveria bassiana | Mycotrol, Botanigard | none | Y | |

| Chromobacterium subtsugae | Grandevo | none | Y | aphids |

| Essential oils (such as thyme and spearmint) | none | Y | slugs and snails | |

| Iron phosphate | Sluggo | none | Y | slugs, snails |

| Kaolin clay | none | Y | flea beetle | |

| Potassium salts | M-Pede | none | Y | symphylans |

| Pyrethrins | Pyganic | 3A | Y | aphids, cabbage root maggot, flea beetle, cabbage whitefly |

| Spinosad (entrust, Seduce (bait)) | Entrust, Seduce | 5 | Y | cabbage root maggot, lepidopterans, symphylans (bait), slugs, snails |

| Sulfur | Biosul | none | Y |

| Herbicides | |||||

|---|---|---|---|---|---|

| Active ingredient | Products in use (trade name) | Target weeds | Timing | Herbicide Resistance Action Committee Group | Approved for organic use |

| Ammonium thiosulfate | AN-20, ATS | Broadleaf and grasses | Postemergence | none | N |

| Carfentrazone-ethyl | Aim | Broadleaf | Pre- and postemergence | 14 | N |

| Clethodim | Select Max | Broadleaf | Postemergence | 1 | N |

| Clopyralid | Spur | Broadleaf | Postemergence | 4 | N |

| Fluazifop-P-butyl | Fusilade | Broadleaf | Postemergence | 1 | N |

| Oxyfluorfen | Goal, GoalTender | Broadleaf | Pre- and postemergence | 14 | N |

| Paraquat | Gramoxone | Broadleaf and grasses | Postemergence | 22 | N |

| Pendimethalin | Prowl | Broadleaf and grasses | Pre-emergence | 3 | N |

| S-metolachlor | Dual, DualMagnum | Broadleaf and grasses | Pre- and postemergence | 15 | N |

| Sethoxydim | Poast | Broadleaf and grasses | Postemergence | 1 | N |

| Trifluralin | Treflan, Triflurex | Broadleaf and grasses | Pre-emergence | 3 | N |

| Caprylic acid | Suppress | Broadleaf and grasses | Postemergence | none | Y |

| Ammonium Nonanoate | Axxe | Broadleaf and grasses | Pre-emergence | none | Y |

| Fungicides and bactericides | |||

|---|---|---|---|

| Active ingredient | Product(s) in use (trade name) | Fungicide Resistance Action Committee Group | Approved for organic use |

| Azoxystrobin | Quadris | 11 | N |

| Cyazofamid | Ranman | 21 | N |

| Mefenoxam | Ridomil Gold | 4 | N |

| Penthiopyrad | Fontelis | 7 | N |

| Propiconazole | Tilt | 3 | N |

| Trifloxystrobin | Flint | 11 | N |

| Bacillus amyloliquefaciens | Double Nickel | BM02 | Y |

| Bacillus pumilus | Sonata | Not classified | Y |

| Bacillus subtilis | Serenade | BM02 | Y |

| Cerevisane | Romeo | Not classified | Y |

| Copper | Nu-Cop and various other coppers | M1 | Y |

| Hydrogen peroxide & peroxyacetic acid | Oxidate or Sanidate | Not classified | Y |

| Potassium bicarbonate | Kaligreen | Not classified | Y |

| Streptomyces lydicus | Actinovate | BM02 | Y |

| Sulfur | None specified | Not classified | Y |

| Trichoderma spp. | Asperello, Bio-Tam, RootShield, Tenet | Not classified | Y |

The PAMS approach

PAMS — Prevention, Avoidance, Monitoring, Suppression — is a classification system for IPM developed for federal agencies adopting IPM practices by farmers. See Appendix A for an overview of the PAMS classification. This system provides a simple way to categorize some examples of the IPM tactics that producers currently utilize in their production systems.

Current general best management practices by fresh market brassica producers in northwest Oregon and southwest Washington

General

Prevention — before the pest has established or appeared

- Be mindful of past pressure in planting beds.

- Rotate crops in a bed throughout the year (for example, do not plant brassicas in direct succession) or plant different crops annually to break pest and diseases cycles.

- Avoid planting adjacent to fields that were diseased or infested the previous season.

- Monitor soil moisture or humidity levels to prevent ideal conditions for diseases favored by high levels or extended periods of a wet canopy or excessively wet soil conditions.

- Avoid overhead irrigation to prevent issues that can result from wet foliage or standing water.

- Monitor soil health and fertilizer levels to create resilient crops.

- Avoid excess nitrogen and other fertilizers.

- Use an optimum, balanced fertility regime.

- Transplant larger and more resilient plants or plant-resistant varieties (if available for the specific diseases and pests of concern).

- Remove weeds and maintain noncrop areas to reduce pest and disease habitats.

- Choose crops resilient to or less difficult to manage for problem pests in your region (for example, Brussels sprouts may be too costly to manage for aphids in some areas).

- Rotate out of crucifers for at least three years and manage cruciferous weeds.

- Control pathogen-susceptible weeds and volunteers in between cropping with crucifers.

- Purchase seed that has been tested and shown not to be infected with certain pathogens of concern in this region (for example, the Alternaria black spot pathogens Alternaria brassicae and A. brassicicola, the black leg fungus Phoma lingam, the chlorotic leaf spot fungus Pyrenopeziza brassicae, and the black rot bacterial pathogen, Xanthomonas campestris pv. campestris). Seed that has not been tested can be treated with a hot water treatment (see Vegetable Seed Treatment).

- Remove and destroy symptomatic older leaves or even whole plants early in a disease outbreak for leaf spots and mildews.

- Bury or remove brassica residues after harvest.

- Remove insect pests or disease inoculums that be present.

Avoidance — after the pest has appeared but is not yet a significant problem

- Avoid disturbing soil beds after preparation to prevent weed seed germination.

- Maintain noncrop areas with plants that attract and support desired natural enemies of plant pests.

- Respond rapidly to pest and disease problems before they become too big to control.

Monitoring — key pests are present

- Monitor for key pests, diseases and weeds. Use direct observation, insect traps (sticky traps), trap crops or indicator crops.

- Accurately identify pests to determine response. Obtain professional diagnostic assistance, if needed.

- Use available resources, such as university Extension personnel and plant diagnostic clinics, to assist with an accurate diagnosis and selection of appropriate integrated management practices (see Further reading and resources).

Suppression — Actions are necessary to prevent economic losses

- Chemical

- Carefully select products approved and labeled for use to manage the identified pest, weed or disease.

- Apply products only when necessary, based on monitoring and thresholds (if known).

- Biological:

- Release appropriate natural enemies for pests, when available.

- Plant and maintain noncrop areas with plants that attract natural enemies. Specific plants may vary depending on desired insects and key pests.

- Mechanical:

- Weeds: Hand-pull or use machinery (tine weeders or cultivators) to remove weedy plants.

- Insects: Implement exclusion practices such as the use of Reemay or other row covers.

Top pests affecting brassica production in northwest Oregon and southwest Washington

In surveys, interviews and meetings, participants identified several pests as current concerns. These are not all pests for the industry, and the pest list is not ranked in order of importance to the industry. The working group identified certain pests as a high priority, and those are noted on the following list. Links, where provided, connect to IPM management information or pest profiles.

The following tables represent management practices utilized by brassica growers for key pests, as reported by project participants. An * following an active ingredient (AI) indicates there were OMRI/Organic Use Certified products containing that AI available at the time of preparing this PMSP.

Table 4. Invertebrate pests and IPM methods reported by brassica growers

Aphids:

- Cabbage aphid, Brevicoryne brassicae

- Green peach aphid, Myzus persicae

Notes:

- Aphids can spread within and from greenhouses to the field on transplants.

- Chemical controls: most conventional products are effective, but organic products are considered moderate to least effective.

- Sprayer technology and application methods affect how well chemical controls work.

- Biocontrol agents (natural enemies) were considered effective against aphids by most members of the working group and aid in management of additional pests besides aphids.

- Winged aphids may move back to the crop on stripped leaves left in the field.

- Pest is a problem from midsummer through winter.

- Proximal pest, can move from neighboring crops.

- Primary pest because of product rejection issues at markets. Product has to be cleaned or tossed, frustrating producers.

Management methods reported by brassica growers by production stage:

PREPLANT

Suppression: biological

- Biocontrol in greenhouse transplant production: Aphidoletes (aphid midge)

TRANSPLANT AND SEEDING

Suppression: chemical

- Imidacloprid (reported by participants as less effective in recent years, resistance is a concern)

- Cyantraniliprole (apply within first three weeks after planting)

CROP DEVELOPMENT

Avoidance

- Support natural enemy habitats.

- Irrigation ( regular irrigation can stop small populations from increasing).

- Monitor fertilization (high nitrogen in soil can increase populations).

Suppression: chemical

- Pyrethrin*

- Multiple sprays (2–3 weekly applications)

- Chromobacterium subtsugae (Grandevo)*

- Rotations of Beauvaria bassiana, and potassium salts (M-PEDE)* and pyrethrin

- (Note: Do not tank mix Bb with other products)

- Azadirachtin*

- Imidacloprid

- Thiamethoxam

- Flonicamid

- Afidopyropen

- Cyantraniliprole

Suppression: mechanical

- Strip leaves (labor-intensive)

Suppression: biological

- Release agents: lacewings, minute pirate bug, ladybugs, assassin bugs.

- Support natural enemy habitats.

HARVEST

Monitoring

- Frequent scouting and inspection of plants during harvest.

Suppression: mechanical

- Strip leaves (kales, collards); remove lower leaves

- Water sprays (Brussels sprouts): peel back leaves and spray aphids off (time- and labor-intensive).

- Discard heads (broccoli): if aphids are in heads, have to discard heads.

Suppression: chemical

- Same list as "Crop development."

- Weekly applications.

- Effective, but do not last as long as in prior years, suggesting possible resistance of pests to some products.

- Do not apply in windy conditions to reduce drift.

Cabbage root maggot (Delia radicum)

Notes:

- High-priority pest.

- Problematic for root crops.

- Appears as soon as there is reasonable flying weather for adults.

- Primary pest early in the season but can be problematic all season.

Management methods reported by brassica growers by production stage:

TRANSPLANT/SEEDING

Prevention

- Do not plant fields with brassicas in back-to-back seasons or within a half-mile of an infested field.

- Remove infested crop residues from fields to reduce reinfestation.

Avoidance

- Limit irrigation to let eggs desiccate.

Monitoring

- Predict adult flights using degree-day models.

- Set pan traps at field edges in early spring.

- If detected, look for damage in crops

Suppression: chemical

- Cyantraniliprole (2–3 days before planting).

- Zeta-cypermethrin

- Bifenthrin

CROP DEVELOPMENT

Prevention

- Exclusion: Use row cover (if applied early) such as insect netting or Remay.

Avoidance

- Plant mature transplants (more resilient to damage than small plants).

- Seed early and harvest early (get ahead of the pest population).

Suppression

- Trap cropping combined with applications of insecticides.

- Zeta-cypermethrin

- Bifenthrin

- Spinosad*

- Pyrethrin*

- Nematodes are not effective.

Flea beetles

- Crucifer flea beetle, Phyllotreta cruciferae

- Hop flea beetle, Psylliodes punctulata

- Striped flea beetle, Phyllotreta striolata

Notes:

- High-priority pest.

- Chemical treatments are ineffective once populations are high.

- High pressure in kale, broccoli and cabbage.

- Once established, flea beetles are difficult to manage.

- In situations where infestations are high. A spray regime can be more costly than the products are worth. Economic thresholds are reached or passed frequently for this pest.

Management methods reported by brassica growers by production stage:

TRANSPLANT/SEEDING

Prevention/avoidance

- Exclusion: Row cover such as Remay.

- If flea beetles infest direct-seeded plants, it is easier to replant than try to manage flea beetles.

Suppression: chemical

- Azadiractin / neem oil* (effective if populations are small)

- Kaolin clay* (Treat trays of seedlings on small-scale farms to prevent feeding and act as a deterrent. Wash it off before harvest; it can slow the growth of crops if you leave it on.).

- Pyrethrin*

- Spinosad*

CROP DEVELOPMENT

Suppression: chemical

- Azadirachtin* (multiple sprays weekly)

- Spinosad*

- Pyrethrin/azadirachtin mix*

- Carbaryl

- Bifenthrin

- Zeta-cypermethrin

- Thiamethoxam

- Products applied 2–3 times, as needed, rotated on a 7- to 14-day interval.

Lepidoptera (moths and butterflies)

- Cabbage white butterfly, Pieris rapae

- Cabbage looper, Trichoplusia ni

- Diamondback moth, Plutella xylostella

Armyworms and cutworms

- Bertha armyworm, Mamestra configurata

- True armyworm, Mythimna unipuncta or Pseudaletia unipuncta

- Western yellowstriped armyworm, Spodoptera praefica

- Black cutworm, Agrotis ipsilon

Notes:

- Winter cutworm is a problem early season, others in spring through fall.

- Cabbage looper can be a greenhouse pest in the winter.

Management methods reported by brassica growers by production stage:

PLANTING

Monitoring

- Frequent scouting

Suppression: chemical

- Preventatives alternating:

- Cyantraniliproile

- Indoxacarb

- Bifenthrin

- Chlorantraniliprole

- Bacillus thuringiensis (BtK)

- Zeta-cypermethrin

- Spinetoram

- Applied every 2–3 weeks, ahead of the pest problem.

CROP DEVELOPMENT

Avoidance

- Exclusion (row cover).

- Biocontrol, support natural enemies.

Suppression: biological

- Support natural enemies.

Suppression: chemical

Preventative, alternating applications of products:

- Indoxacarb

- Bifenthrin

- Chlorantraniliprole

- Bacillus thuringiensis* (BtK) (Bt is effective against diamondback)

- Pyrethrin*

- Spinosad*

- Zeta-cypermethrin (Zeta-cypermethrin resistance is documented).

- Spinetoram (noted as effective).

- Cyantraniliprole

- None of the pyrethroids is effective against diamondback moth.

HARVEST

Monitoring

- Check for larvae, holes from chewing damage, adults.

- Some sweep netting may help to detect the pests.

Suppression: chemical

- Chemical sprays as needed, with monitoring weekly, as long as the preharvest interval restriction is followed (see list above for products).

Symphylans garden symphylan, Scutigerella immaculata

Notes:

- High priority for management in small-scale, organic production.

- Problem in organic and conventional brassica production.

- High organic matter in a field can increase problems with symphylans.

- Manures can increase symphylan problems.

- May be coming back because the insecticide Lorsban is no longer registered for use in brassica crops.

Management methods reported by brassica growers by production stage:

TRANSPLANT / SEEDING

Prevention/avoidance:

- Use healthy transplants

- Mature transplants can be more resilient than small seedlings.

- Rotation

- Scout for damage and, if detected, rotate to at least one planting of potato.

- Record hotspots in a field and avoid planting in that location.

- Any crops planted in early spring are sensitive to symphylans.

- Rotation is effective but additional solutions are needed.

Suppression: biocontrol

- Entomopathogenic nematodes

Suppression: chemical

- Thiamethoxam (can only be used once per crop cycle)

- Spinosad baits* applied at planting or banded along the base of plants

Mollusks

Snails

- Brown garden snail, Cornu aspersum

Slugs

- Grey field slug, Deroceras reticulatum

- Arion spp., including

- Arion hortensis

- Arion rufus

- Arion circumscriptus

- Tramp slug, Deroceras invadens

- Marsh slug, Deroceras laeve

- Greenhouse slug, Milax gagates

Notes

- Slugs rarely are an issue at planting for conventional growers.

- Metaldehydes are used mostly in conventional production, not in organic production.

- Metaldehydes tend to work better than iron-based products.

- Efficacy is extremely variable based on environmental conditions.

- Sluggo helps to supplement other practices or can be placed in areas where slugs and snails congregate (under wooden boards placed in or adjacent to crops).

- Toads were reported to feed on slugs and snails in one organic farm. Support toads in the field by providing habitat and considering potential pesticide effects on amphibians (but this could be a food safety issue).

- Must consider conditions for effective applications, including timing of application in relation to harvest of the crop.

- Once slugs are in the heads of brassicas, they are hard to remove as this is an ideal microhabitat.

Management methods reported by brassica growers by production stage:

PREPLANT / PROPAGATION

Avoidance:

- Tillage and plowing have mixed effectiveness, more may be slugs or snails coming into a crop from adjacent crops.

Suppression

- Chemical

- Iron phosphate baits* (may not be effective)

- Sulfur baits*

- Mechanical: physical removal — hand-pick (laborious).

- Biological: toads were reported to feed on slugs and snails in one organic farm. Support toads in the field by providing habitat and considering potential pesticide effects on amphibians (but this could be a food safety issue).

CROP DEVELOPMENT

Avoidance

- Manage before the button stage of broccoli or cauliflower.

- Some weeds are listed as problematic in that they are attractive to slugs (shelter, food source), so reduce weed populations along with using baits.

- Mow and manage weeds to reduce habitat suitable for slugs and snails.

- Avoid excess moisture in canopy to discourage conditions conducive to slugs and snails.

Suppression: chemical

- Sluggo (iron phosphate)*

- Sulfur baits*

- Metaldehydes used in the fall before conditions become too wet and before eggs are laid, before fall rains, to kill of the next population.

- Smaller the pellet, the better for baits. Efficacy is greater but it can be harder to spread smaller pellets.

- Essential oils*: Thyme, spearmint and garlic oil, but these can be phytotoxic to some brassica crops.

Suppression: mechanical

- Physical removal: Hand-pick

HARVEST

Suppression: mechanical

- Physical removal: hand-pick (laborious)

Suppression: chemical

- Sulfur baits*

Seed corn maggot, Delia platura

Notes:

- Organic management is strictly cultural, as there are no organic chemical management options (spinosad has minimal effect).

Management methods reported by brassica growers by production stage:

PREPLANT

Prevention/avoidance:

- Cover crops and manure must be worked in four weeks before planting.

Monitoring

- Watch pest models for appropriate timing of applications.

- Yellow sticky plates should be moved higher as the canopy height increases.

PLANTING

Suppression: chemical

- Cyantraniliprole

- Bifenthrin

Cabbage whitefly, Aleyrodes proletella

Low priority, not consistently a difficult pest to manage.

Management methods reported by brassica growers by production stage:

- Insecticides

- Pyrethrins* (effective)

- Azadirachtin*

Nematodes

Sugar beet cyst nematode, Heterodera schachtii

Minor pest when wet and muddy.

Management methods reported by brassica growers by production stage:

SEASONLONG

Suppression: chemical

- Melocon WG*

- Fumigation prior to planting (expensive and might not be worth it for such a minor pest)

Western flower thrips, Frankliniella occidentalis

- Issue in Central and Eastern Oregon and Washington because of the semi-arid, warm climate.

- Can build very high densities in hot weather.

Management methods reported by brassica growers by production stage:

CROP DEVELOPMENT

Suppression: chemical

- Methomyl

- Spinetoram

- Zeta-cypermethrin

Table 5: Weeds and IPM methods reported by brassica growers

Stage: preplanting

Species: broadleaves

- Amaranth, pigweed, Powell amaranth (Amaranthus spp.)

- Chickweed (Stellaria media), mouse ear chickweed (Cerastium fontanum)

- Groundsel (Senecio vulgaris)

- Ladysthumb, smartweed (Polygonum persicaria)

- Lambsquarters (Chenopodium album)

- Nightshades

- Hairy (Solanum physalifolium)

- Black (Solanum ptychanthum)

- Prickly lettuce (Lactuca serriola)

- Purslane (Portulaca oleracea)

- Shepherd's purse (Capsella bursa-pastoris)

- Sowthistle (Sonchus spp.)

- Speedwell (Veronica spp.)

- Wild radish (Raphanus raphanistrum)

- Other brassicas (birdsrape, mustards, Brassica spp.)

Species: grasses

- Annual bluegrass Poa annua

- Annual ryegrass

- Fescues: tall, fine, creeping red

- Quackgrass, Elymus repens

- Crabgrass, Digitaria sanguinalis

Management: prevention and avoidance

- Disk cover crops.

- Weeds sometimes tilled into the ground before planting (green manure).

- Don’t move soil after bed preparation for risk of disturbing weed seeds.

- Stimulate or allow weed germination and remove emerging weeds for one to two seasons to deplete the seed bank in problematic areas.

Management: mechanical suppression

- Flame-weeding

Management: chemical suppression

Pre-emergent applications of herbicides

- S-metolachlor, Group 15)

- Not labeled on many brassica crops, mostly on seed crop labels

- Oxyfluorfen (Group 14) pretransplant application only

- Trifluralin, Group 3

- Mixed into soil (PPI)

- Caprylic acid*

- Ammonium nonoate

Notes and comments:

- Lots of options for burndown or broad-spectrum herbicide applications, but no or few selective herbicides are registered for brassica crops.

- Some brassica transplants can receive applications of selective herbicides during crop development for grass control later, if needed and label allows.

- Problem: No label for Treflan on turnips.

- Would like to see more research on laser weeding and precision agriculture for brassicas.

Stage: transplant/seeding

Species: broadleaves

- Amaranth, pigweed, Powell amaranth (Amaranthus spp.)

- Chickweed (Stellaria media), mouse ear chickweed (Cerastium fontanum)

- Henbit (Lamium amplexicaule)

- NIghtshade

- Hairy (Solanum physalifolium)

- Black (Solanum ptychanthum)

- Purslane (Portulaca oleracea)

- Ladysthumb, smartweed (Polygonum persicaria)

- Lambsquarters (Chenopodium album)

- Shepherd's purse (Capsella bursa-pastoris)

- Speedwell (Veronica spp.)

- Red deadnettle (Lamium purpureum)

- Other brassicas (birdsrape mustards, other Brassica spp.)

Species: sedges and rushes

- Nutsedge (Cyperus esculentus)

- Toad rush (Juncus bufonius)

Management: avoidance

- Don’t move soil after bed preparation for risk of disturbing weed seeds

Management: mechanical suppression

-

- Weed every one to three weeks, starting right after transplant or seeding.

- Hand-pull weeds.

- Cultivate with a tractor-mounted cultivator.

- Some flame-weeding

Management: chemical suppression

- S-metolachlor, used in brassica seed crops, effective early season, not effective for lambsquarters.

- Oxyfluorfen (pretransplanting)

- Trifluralin (preplanting)

- Paraquat

- Carfentrazone-ethyl

- Vinegar (20–30% acetic acid)* for burndown

- Capyrilic acid*

- Ammonium nonoate*

Notes

- Chickweed sometimes is left as a cover crop.

- Lack of certified organic herbicides registered for control of grass weeds.

- Organic chemical options are weak on grasses, and just a burndown so weeds can come back if managed too late.

- Precision agriculture: Weed zapper (not widely used) or experimental laser weeding may be possible options.

Species: grasses

- Annual bluegrass (Poa annua)

- Annual ryegrass

- Fescues: tall, fine, creeping red

- Quackgrass (Elymus repens)

- Crabgrass (Digitaria sanguinalis)

Management: mechanical suppression

- Weed every one to three weeks, starting right after transplanting or seeding.

- Cultivate with a tractor-mounted cultivator.

- Hand-pull (labor-intensive and expensive).

Notes:

- No flame weeding — not effective against grasses

Stage: crop development

Species: broadleaves (same as above, plus:)

- Dock (Rumex spp.)

- Field bindweed (Convolvulus arvensis)

- Purslane (Portulaca oleracea)

Management: exclusion

- Biodegradable mulches

- Weeds can pop up in holes in the mulch

- There are many types of mulch and tarping options for organic weed control with spring or fall brassicas.

Management: competition

- Brassicas can outcompete nutsedge.

- Appropriate fertilizer programs can help plants compete with weeds.

Management: mechanical suppression

- Solarization

- Biofumigation (mustards or mustard seed meal under clear plastic)

- Hand-pull weeds

- Hand-hoe weeds

- Tractor-mounted cultivation (finger or tine weeders)

Management: chemical suppression

- Ammonium thiosulfate (AN–20) to burn off weeds with nitrogen fertilizer. Commonly used in B. oleracea production, mainly for fertility, but provides ancillary weed control of important weeds like shepherd's purse

- Pendimethalin

- Clopyralid (for nightshade and pigweed control)

Notes

- Weed pressure changes with the weather.

- Must have a routine of mechanical steps to reduce weeds, reduce current pressure but also next year’s pressure.

- Can get out of hand with unseasonable rains and labor shortage.

- Few products can be applied during crop production.

In one example of an emerging technology, tractors tow a hoeing machine called a Robovator. This works for transplanted crops, but probably not for direct-seeded crops. It may have better success in broccoli and cabbages.

Species: grasses

- Annual bluegrass (Poa annua)

- Annual ryegrass

- Fescues: tall, fine, creeping red

- Quackgrass (Elymus repens)

- Crabgrass (Digitaria sanguinalis)

- Barnyard grass (Echinochloa crus-galli)

Suppression: chemical

- Clethodim (generally effective, although some weeds developing resistance)

- Sethoxydim

- Fluazifop-P-butyl

Notes

Especially problematic in brassica root crops.

Stage: Harvest

Broadleaves: all above plus:

- Canada thistle (Cirsium arvense)

Management: chemical suppression

- Clopyralid

Notes

- Thistle gets in the way of harvest, moves around tractors, and is hard to manage.

- “Weed lickers/wipers” and discs used if weeds are present before harvest. The applicator must pay attention to preharvest intervals of specific products and use caution as some products can hurt crops (phytotoxicity).

- Thistle seeds look like frass in or on the harvested product, leading to rejection issues. Education about this to processors is crucial.

- Issues with thistle where frequent irrigation is used.

Table 6: Pathogens and IPM methods reported by brassica growers

Black leg (Phoma stem canker) [Plenodomus lingam (syn. Leptosphaeria maculans, anamorph: Phoma lingam) and Plenodomus biglobosus (syn. Leptosphaeria biglobosa)]

Prevention and avoidance

- Rotate out of crucifers for at least three years.

- Control susceptible weeds and volunteers (crucifers) in between cropping with crucifers.

- Use tested, pathogen-free seed. Seed not known to be clean may be treated in water at 122°F for 15–30 minutes.

- Remove and destroy symptomatic older leaves early in an outbreak.

- Bury or remove crucifer residues after harvest.

Monitoring

- Scout fields to monitor diseases.

Suppression

- Use fungicide seed treatments (pyraclostrobin + boscalid, or thiabendazole).

- Use a protective spray program based on scouting.

- Apply efficacious products such as pyraclostrobin, difenconazole + cyprodinil, fluxapyroxad + pyraclostrobin, difenconazole + azoxystrobin, triflumizole, and tebuconazole formulations.

Leaf and stem diseases

- Diseases caused by Alternaria spp. (black spot, gray leaf spot) (fungi: Alternaria brassicae and A. brassicicola)

- Chlorotic leaf spot (fungus: Cylindrosporium concentricum)

- Downy mildew (oomycete: Peronospora parasitica)

- Gray mold (fungus: Botrytis cinerea)

- Powdery mildew (fungus: Erysiphe cruciferarum)

- Sclerotinia stem rot and watery soft rot (fungus: Sclerotinia sclerotiorum)

- White leaf spot and gray stem (fungus: Neopseudocercosporella capsellae)

Prevention and avoidance

- Rotate out of crucifers for at least three years and manage cruciferous weeds.

- Avoid planting adjacent to fields that had diseased crops the previous season.

- Plant resistant varieties, if available.

- Avoid excess application of nitrogen fertilizers; use an optimum, balanced fertility regime.

- Control susceptible (crucifer) weeds and volunteers between cropping with crucifers.

- Use tested, pathogen-free seed (Alternaria spp. and chlorotic leaf spot). Seed not known to be clean may be treated in water at 122°F for 15–30 minutes.

- Remove and destroy symptomatic older leaves early in the disease outbreak for leaf spots and mildews.

- Bury or remove crucifer residues after harvest.

Monitoring

- Scout fields to monitor diseases.

Suppression

- Use fungicide seed treatments (pyraclostrobin + boscalid, thiabendazole for chlorotic leaf spot, Alternaria pathogens, and gray mold; mefenoxam for downy mildew).

- Use a protective spray program.

- Use specific fungicides labeled for the crop (acibenzolar-S-methyl, ametoctradin + dimethomorph, boscalid, chlorothalonil, chlorothalonil + oxathiapiprolin, copper formulations, cyazofamid, cyprodinil + fludioxonil, demethylation-inhibiting formulations, difenconazole + azoxystrobin, difenconazole + cyprodinil, dimethomorph, fluazinam, fluopicolide, flutriafol, fluxapyroxad + pyraclostrobin, mancozeb + azoxystrobin, mandipropamid, mefenoxam + chlorothalonil, oils, oxathiapiprolin + mandipropamid, penthiopyrad, phosphonates, potassium bicarbonate, pydiflumetofen + fludioxonil, strobilurin formulations, and sulfur formulations are labeled for certain brassica diseases; Horticultural mineral oil and extract of Reynoutria sachalienensis are OMRI approved for certain brassica diseases).

- Biological control formulations (Bacillus amyloliquefaciens strain D747, Bacillus amyloliquefaciens strain F727, Bacillus mycoides isolate J, Bacillus pumilis strain QST 2808, Bacillus subtilis strain QST 713 formulations, cerevisane, extract of Swinglea glutinosa, and Streptomyces lydicus) are registered for certain brassica diseases.

Notes

- Very few resistant varieties are available.

- Very limited fungicide options are available for certified organic crops.

Bacterial diseases

- Bacterial soft rot, bacterial leaf spot [Pectobacterium carotovorum subsp. carotovorum (syn. Erwinia carotovora var. carotovora)]

- Black rot (Xanthomonas campestris pv. campestris)

- Bacterial leaf blight and bacterial leaf spot (Pseudomonas syringae pathovars)

Prevention and avoidance

- Use a two-year rotation out of crucifers in production fields; use a three-year rotation for transplant beds.

- Contaminated seed or seed that has not been tested can be cleaned by hot water seed treatment of 122°F for 30 minutes.

- Use tested, pathogen-free seed.

- Control cruciferous weeds and insect pests.

- Use resistant varieties, when available.

- Set out plants in rows spaced to facilitate good air movement through the canopy.

- Cultivate carefully to minimize injuring plants.

- Control the frequency of irrigation and use clean irrigation water.

- Minimize overhead irrigation, if possible. If it must be used, time irrigations so that plants dry rapidly after irrigation.

- Shred and incorporate into the soil any diseased crop refuse promptly after harvest to hasten breakdown of infected plant material on which the bacteria survive.

- Do not plant brassica crops the following year if the field has a significant level of infection.

- Clean and spray storage walls and floors.

- In storage, use a buffering material such as straw or paper to prevent injury to the heads.

- Keep storage house humidity between 90% and 95% and the temperature between 32°F and 39°F.

Monitoring

- Scout fields to monitor for symptoms of diseases.

Suppression

- Acibenzolar-S-methyl can be applied at regular intervals but is phytotoxic to some cultivars.

- Apply copper sprays at regular intervals.

- Extract of Reynoutria sachalienensis can be applied at regular intervals.

- Biological control formulations (Bacillus subtilis strain QST 713) are available for brassicas.

Damping-off, wirestem, stem rot. and root rots [fungi: Fusarium spp., Rhizoctonia solani; oomycetes: Phytophthora megasperma, Pythium spp., Aphanomyces raphani (black root rot)]

Prevention and avoidance

- In the greenhouse or seedbed, pasteurize the soil with heat. Use good sanitation practices in greenhouses.

- Locate seedbeds on well-drained soil, and avoid excessive irrigation.

- Practice a three-year rotation with nonsusceptible crop species.

- Space rows or seedlings in the seedbed to maximize air movement.

- Carefully examine seedlings when transplanting; discard any with symptoms of wirestem or root rot

- If damping-off occurs, stop watering for a while. Allow soil to dry around the plants. If the seedlings are in flats or cold frames, give the seedlings as much air movement and light as possible.

- Crop rotation with cereals may reduce some pathogen populations in the soil.

- Remove or encourage decomposition of plant debris by flail mowing to break up the residues, followed by incorporation into the soil.

Monitoring

- Scout fields to monitor for disease symptoms

Suppression

- Fungicides

- Seed treatments (metalaxyl formulations for oomycetes, captan, azoxystrobin, fludioxonil, and thiram)

- Drenches and fumigation (metalaxyl, azoxystrobin, flutolanil, and metalaxyl + azoxystrobin)

- Biofungicides (Bacillus amyloliquefaciens strain D747, Bacillus subtilis strain QST 713, Gliocladium catenulatum strain J1446, Gliocladium virens, Streptomyces griseoviridis strain 61, Streptomyces lydicus, Trichoderma asperellum + T. gamsii formulations, and Trichoderma harzianum Rifai strain T-22)

Wilt (fungi: Fusarium oxysporum f. sp. raphani, F. oxysporum f. sp. conglutinans, Verticillium longisporum)

Cultural controls

- Plant-tested, pathogen-free seed in pathogen-free soil, where possible.

- Avoid establishment of brassica seed crops in soils with high levels of plant residues or organic amendments.

- Time planting to avoid excessively warm soil conditions and high transpirational demand

- Remove and destroy infected plants.

- Clean soil from equipment, tools and clothing after working in an infested field.

- Rotate out of susceptible crops for a minimum of four years.

Diseases of high priority

Clubroot (Cercozoa: Plasmodiophora brassicae)

- Plant in new ground that has not been rotated to crucifers.

- Three or more years of rotation out of crucifers.

- Control cruciferous weeds.

- Work in pathogen-free fields first, then clean equipment before moving to other fields

- Amend soils with agricultural limestone so that the soil pH is above 7.0.

- Incorporate hydrated lime at 1,500 lb/A at least six weeks before planting, whether pH is neutral or alkaline, to give additional disease control.

- Hill infected plants to encourage adventitious root formation.

- Soil solarization with plastic can weaken resting spores.

- Omega 500F at 6.45 fluid ounces per 100 gallons as a transplant drench or 2.6 pints per acre as a soil incorporation.

- Ranman 400SC at 12.9– 25.75 fluid ounces per 100 gallons as a transplant drench or 20 fluid ounces per acre as a soil incorporation.

- Prestop as a soil drench or incorporated into the transplant growing medium, apply at seeding and repeat 7–14 days later for best suppression of clubroot.

Table 7: Vertebrate pests and IPM methods reported by brassica growers

Species: Small rodents

- Mice

- Rats

- Voles

Management: prevention

- Cut grass adjacent to crops to reduce potential habitat

- Till before planting

Management: suppression

- Few legal options in the field.

- Outside the field, use bait stations.

- Vitamin D-3 baits*: certified for organic production but must be 50 feet away from the structure in which transplants are produced.

Notes

- Rodents are a high-priority issue for brassica producers.

- A “Voles, drones and dogs” workshop was offered by OSU Extension in 2022. Information about the project is available at https://blogs.oregonstate.edu/voles/.

- Tillage tends to reduce voles significantly in fields.

Species: Large rodents

- Gophers

- Gray squirrels

Management: mechanical

- Trap, relocate.

Species: deer, elk

Avoidance/suppression: mechanical

- “Irish Spring” soap on sticks placed at ends of rows, 1 per 100 feet. The smell is a deterrent, but there is only anecdotal evidence of efficacy.

- Flashy/shiny objects.

- Guns/hunting.

Avoidance: chemical

- Chemical deterrent (Plantskydd*, Deer-Off, Penergetic, hot sauce).

- Blood meal at the borders of fields.

- Noise-making devices.

Notes

- Increased pressure on some farms possibly because of decreased logging nearby.

- Increased pressure on some farms because nearby vineyards are erecting elk and deer fencing.

- Nothing is reported as very effective.

- Can be a very costly pest because of feeding and walking damage to crops.

Species: Rabbits

- Plantskydd (sprayable blood meal)*

- Hot sauce and spicy deterrents

Avoidance: mechanical

- Scarecrows

- Bird guns

- Netting

Notes

- Not many management options

- Low-priority pest but can be destructive

Species: birds, crows and geese

Avoidance: mechanical

- Scarecrows

- Bird guns

- Netting

Minor pests, emerging pests and other concerns

Root aphids (undetermined species, possibly Pemphigus populicaulis):

Mentioned as an occasional problem

More information:

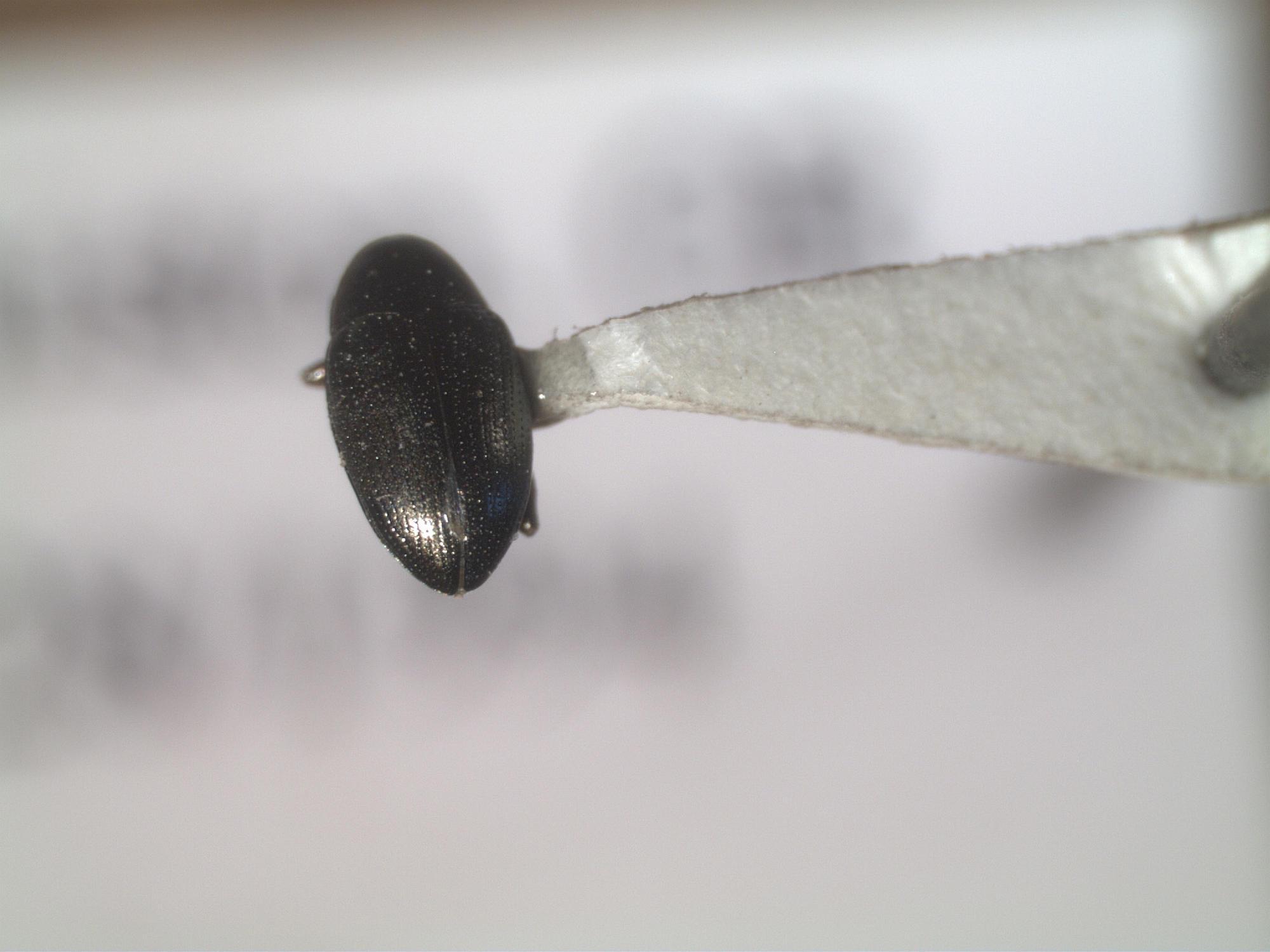

Wireworms (Coleoptera: Elateridae)

Reported as problematic in root vegetables

Beet leafhopper (Circullifer tenellus)

Pyrethroids are effective, but the concern is that leafhoppers can spread viruses (for example, beet curly top virus) and phytoplasmas (aster yellows and beet leafhopper transmitted virescence agent, which can be very severe on radish).

Smartweed (Polygonum punctatum):

Pesticide resistance development in insects, weeds and pathogens to some active ingredients currently used.

Reported: Some pesticide chemistries that are effective in the Pacific Northwest have been reported to be less effective in targeting pests in other states due to documented development of pesticide resistance. Specifically, there is a concern that brassica growers in the Pacific Northwest will experience increased pressure from diamondback moth (Lepidoptera: Plutella xylostella). In addition, resistance to herbicides by weeds from repeated or overuse of single modes of action was mentioned as an ongoing concern for the industry.

More information

Herbicide Resistance Action Committee Global

Insecticide Resistance Action Committee

Fungicide Resistance Action Committee

Further reading and resources

- Pacific Northwest Disease, Pest, and Weed Management Handbooks

- OSU Extension Catalog

- WSU Extension Catalog

- National IPM Database

- Pacific Northwest Vegetable Association

- WSSA Herbicide Resistance Action Committee

- Insecticide Resistance Action Committee

- Fungicide Resistance Action Committee

- Herbicide Resistance Action Committee Global

- Pacific Northwest Vegetable Extension Group (PNW VEG)

- WSU HortSense

- OSU Plant Clinic

- WSU Puyallup Plant & Insect Diagnostic Laboratory

- Washington State University Plant Pest Diagnostic Clinic

Acknowledgements

Thanks to growers, crop consultants and Extension personnel who provided pest management information, comments and suggestions to improve this report. Thanks to Michelle Armstrong for recruiting participants and gathering information and current management information. Thanks to Dave Losh, Oregon State statistician, for providing vegetable production statistics. Thank you to Silvia Rondon for help at the working group meeting in Wilsonville, Oregon, coordinating the peer-review process and presenting this publication to our stakeholders. Special thanks to our blind peer-reviewers for their suggestions, comments, insight and improvements to the report.

This project was funded in part by the USDA National Institute of Food and Agriculture, through the Western Integrated Pest Management Center, with additional support from USDA Crop Protection and Pest Management Extension Implementation Program.

Appendix: Using PAMS terminology

This system of terminology for IPM was developed for use by U.S. federal agencies seeking to support adoption of IPM by farmers. The table below summarizes common tactics used in agricultural IPM using a “Prevention, Avoidance, Monitoring, Suppression” classification. We also define (in italics) the ecological purpose that lies behind a particular practice. The PAMS tables throughout the text provide a simple basis for surveying practices that are used at different crop growth stages in terms of their contribution to a comprehensive IPM program.

Prevention

Prevent introduction to the farm

- Pest-free seeds, transplants

Prevent reservoirs on the farm

- Sanitation procedures

- Eliminate alternative hosts.

- Eliminate favorable sites in and off crop.

Prevent pest spread between fields on the farm

- Cleaning equipment between fields

Prevent pests developing within fields on the farm

- Irrigation scheduling to prevent disease development

- Prevent weed reproduction.

- Prevent pest-susceptible perennial crops by avoiding high-risk locations.

Avoidance

Avoid host crops for the pest

- Crop rotation

Avoid pest-susceptible crops

- Choose genetically resistant cultivars.

- Choose cultivars with growth and harvest dates that avoid the pest.

- Place annual crops away from high-risk sites for pest development (even parts of a field).

Avoid crop being the most attractive host

- Trap cropping

- Use of pheromones

- Use crop nutrition to promote rapid crop development.

Avoid making the crop excessively nutritious

- Use nutrition to promote rapid crop development.

- Avoid excessive nutrients that benefit the pest.

Avoid practices that increase the potential for pest losses

- Narrow row spacing

- Optimized in-row plant populations

- No-till or strip till

Monitoring

Collect pests

- Scouting and survey approaches

- Traps

Identify pests

- Use of identification guides, diagnostic tools and diagnostic laboratories

Identify periods or locations of high pest risk

- Use weather-based pest-development and risk models.

- Use soil and plant nutrient testing.

Determine status and trends in pest risks and classify pest severity

- Maintain pest records over time for each field.

Minimize pest risks over time

- Plan an appropriate PAMS IPM strategy, based upon pest status and trends.

Determine interventions based upon risks and economics

- Use of decision-support tools, economic thresholds

| Q1: General research topics: Please rank the current importance of these research topics to the PNW brassicas industry | ||||||

|---|---|---|---|---|---|---|

| Topic | Minimum | Maximum | Mean | Standard deviation | Variance | Count |

| 1 Efficacy of biological control agents in brassicas | 1 | 3 | 2.67 | 0.62 | 0.39 | 12 |

| 2 Implementation of biological controls with spray programs | 2 | 3 | 2.57 | 0.49 | 0.24 | 14 |

| 12 Efficacy and timing of irrigation methods (overhead vs. drip) for IPM in brassicas | 1 | 3 | 2.38 | 0.62 | 0.39 | 13 |

| 8 Pesticide products compatible with IPM practices (currently too few) | 1 | 3 | 2.36 | 0.72 | 0.52 | 14 |

| 3 Understand ecological mechanisms of biological control in brassicas | 1 | 3 | 2.31 | 0.72 | 0.52 | 13 |

| 9 Efficacy of targeted or softer chemistries | 1 | 3 | 2.23 | 0.8 | 0.64 | 13 |

| 11 Real-time nitrogen testing on farm (for example, test today to plant tomorrow) | 1 | 3 | 2.14 | 0.64 | 0.41 | 14 |

| 10 Research into additional organically compatible pesticides and products | 1 | 3 | 2.07 | 0.96 | 0.92 | 14 |

| 14 Research into biochar as an amendment | 2 | 2 | 2 | 0 | 0 | 5 |

| 6 Integrated pest management of rodents, including voles | 1 | 3 | 1.86 | 0.64 | 0.41 | 14 |

| 13 Research into insect frass as a fertilizer/soil health improvement | 1 | 3 | 1.83 | 0.69 | 0.47 | 6 |

| 7 Health effects and nutritional content of brassicas produced through organic vs. conventional methods | 1 | 3 | 1.77 | 0.7 | 0.49 | 13 |

| 4 Effective methods of interplanting | 1 | 3 | 1.75 | 0.6 | 0.35 | 12 |

| 5 Integrated pest management of geese | 1 | 3 | 1.54 | 0.63 | 0.4 | 13 |

| Q1: General research topics: Please prioritize the current importance of these research topics to the PNW brassicas industry | |||||||

|---|---|---|---|---|---|---|---|

| Priority | Least importance | Medium importance | Top priority | Total | |||

| 1 Efficacy of biological control agents in brassicas | 8.33% | 1 | 16.67% | 2 | 75.00% | 9 | 12 |

| 2 Implementation of biological controls with spray programs | 0.00% | 0 | 42.86% | 6 | 57.14% | 8 | 14 |

| 10 Research into additional organically compatible pesticides and products | 42.86% | 6 | 7.14% | 1 | 50.00% | 7 | 14 |

| 8 Pesticide products compatible with IPM practices (currently too few) | 14.29% | 2 | 35.71% | 5 | 50.00% | 7 | 14 |

| 9 Efficacy of targeted or softer chemistries | 23.08% | 3 | 30.77% | 4 | 46.15% | 6 | 13 |

| 3 Understand ecological mechanisms of biological control in brassicas | 15.38% | 2 | 38.46% | 5 | 46.15% | 6 | 13 |

| 12 Efficacy and timing of irrigation methods (overhead vs. drip) for IPM in brassicas | 7.69% | 1 | 46.15% | 6 | 46.15% | 6 | 13 |

| 11 Real-time nitrogen testing on farm (for example, test today to plant tomorrow) | 14.29% | 2 | 57.14% | 8 | 28.57% | 4 | 14 |

| 13 Research into insect frass as a fertilizer/soil health improvement | 33.33% | 2 | 50.00% | 3 | 16.67% | 1 | 6 |

| 7 Health effects and nutritional content of brassicas produced through organic vs. conventional methods | 38.46% | 5 | 46.15% | 6 | 15.38% | 2 | 13 |

| 6 Integrated pest management of rodents, including voles | 28.57% | 4 | 57.14% | 8 | 14.29% | 2 | 14 |

| 4 Effective methods of interplanting | 33.33% | 4 | 58.33% | 7 | 8.33% | 1 | 12 |

| 5 Integrated pest management of geese | 53.85% | 7 | 38.46% | 5 | 7.69% | 1 | 13 |

| 14 Research into biochar as an amendment | 0.00% | 0 | 100.00% | 5 | 0.00% | 0 | 5 |

| Q2: Research on pathogens. Please rank the current importance of these research topics to the PNW brassicas industry | |||||||

|---|---|---|---|---|---|---|---|

| Topic | Minimum | Maximum | Mean | Standard deviation | Variance | Count | |

| 5 Management of downy mildew, including scouting, spray timing | 2 | 3 | 2.47 | 0.5 | 0.25 | 15 | |

| 7 Increase infrastructure and resources for crop consultants to recognize and diagnose | 1 | 3 | 2.43 | 0.73 | 0.53 | 7 | |

| 1 Nonchemical based club root management | 1 | 3 | 2.36 | 0.61 | 0.37 | 14 | |

| 2 Efficacy of liming to prevent club root | 1 | 3 | 2.21 | 0.77 | 0.6 | 14 | |

| 4 Management of root rots | 1 | 3 | 2.2 | 0.75 | 0.56 | 15 | |

| 6 Management of emerging pathogens (such as black spot and small leaf spot) | 1 | 3 | 2.14 | 0.64 | 0.41 | 14 | |

| 3 Management of soft rots | 1 | 3 | 2.13 | 0.72 | 0.52 | 15 | |

| Priority | Least Importance | Medium importance | Top priority | Total | |||

| 7 Increase infrastructure and resources for crop consultants | 14.29% | 1 | 28.57% | 2 | 57.14% | 4 | 7 |

| 5 Management of downy mildew, including scouting, spray timing | 0.00% | 0 | 53.33% | 8 | 46.67% | 7 | 15 |

| 1 Nonchemical club root management (for example, cultural practices) | 7.14% | 1 | 50.00% | 7 | 42.86% | 6 | 14 |

| 2 Efficacy of liming to prevent club root | 21.43% | 3 | 35.71% | 5 | 42.86% | 6 | 14 |

| 4 Management of root rots | 20.00% | 3 | 40.00% | 6 | 40.00% | 6 | 15 |

| 3 Management of soft rots | 20.00% | 3 | 46.67% | 7 | 33.33% | 5 | 15 |

| 6 Management of emerging pathogens (such as black spot and small leaf spot) | 14.29% | 2 | 57.14% | 8 | 28.57% | 4 | 14 |

| Q3: Research on weeds: Please rank the current importance of these research topics to the PNW brassicas industry | |||||||

|---|---|---|---|---|---|---|---|

| Topic | Minimum | Maximum | Mean | Standard deviation | Variance | Count | |

| 6 Products that can be applied during crop production | 3 | 3 | 3 | 0 | 0 | 6 | |

| 5 In-row weed management solution for direct seeded crops | 2 | 3 | 2.83 | 0.37 | 0.14 | 6 | |

| 3 Automated weed solutions: smart cultivation tools | 2 | 3 | 2.58 | 0.49 | 0.24 | 12 | |

| 1 More organic herbicide chemistries | 1 | 3 | 1.77 | 0.8 | 0.64 | 13 | |

| 2 Weed management for brassicas in Central and Eastern Oregon | 1 | 3 | 1.77 | 0.8 | 0.64 | 13 | |

| 4 More research into practices for direct seeding in dense beds so crop can shade out weeds | 1 | 3 | 1.67 | 0.75 | 0.56 | 6 | |

| Priority | Least important | Neutral | Most important | Total | |||

| 1 More organic herbicide chemistries | 46.15% | 6 | 30.77% | 4 | 23.08% | 3 | 13 |

| 2 Weed management for brassicas in Central and Eastern Oregon | 46.15% | 6 | 30.77% | 4 | 23.08% | 3 | 13 |

| 3 Automated weed solutions: Smart cultivation tools | 0.00% | 0 | 41.67% | 5 | 58.33% | 7 | 12 |

| 4 More research into practices for direct seeding in dense beds so crop can shade out weeds | 50.00% | 3 | 33.33% | 2 | 16.67% | 1 | 6 |

| 5 in-row weed management solution for direct seeded crops | 0.00% | 0 | 16.67% | 1 | 83.33% | 5 | 6 |

| 6 Products that can be applied during crop production | 0.00% | 0 | 0.00% | 0 | 100.00% | 6 | 6 |

| Q4: Research on Insects and Invertebrates: Please rank the current importance of these research topics to the PNW brassicas industry | |||||||

|---|---|---|---|---|---|---|---|

| Topic | Minimum | Maximum | Mean | Standard deviation | Variance | Count | |

| 1 Management of aphids including scouting, effective products or methods, spray timing | 2 | 3 | 2.86 | 0.35 | 0.12 | 14 | |

| 7 Long-term management of diamondback moth | 2 | 3 | 2.69 | 0.46 | 0.21 | 13 | |

| 13 Management of flea beetles in organic and conventional systems | 1 | 3 | 2.69 | 0.61 | 0.37 | 13 | |

| 12 General management of root maggot — chemical and nonchemical methods | 1 | 3 | 2.64 | 0.61 | 0.37 | 14 | |

| 8 Resistance of diamond back moth to current chemistries | 1 | 3 | 2.54 | 0.63 | 0.4 | 13 | |

| 11 Efficacy of organic insecticide chemistries | 1 | 3 | 2.45 | 0.78 | 0.61 | 11 | |

| 3 Biological control of specific pests: which natural enemies are effective | 1 | 3 | 2.43 | 0.73 | 0.53 | 14 | |

| 6 Resistance of aphids to current chemistries | 1 | 3 | 2.36 | 0.72 | 0.52 | 14 | |

| 5 New or updated management of symphylans | 1 | 3 | 2.25 | 0.72 | 0.52 | 12 | |

| 2 Management of slugs (beyond Sluggo and mowing) | 1 | 3 | 2.21 | 0.77 | 0.6 | 14 | |

| 4 Metrics on measuring efficacy of biological control | 1 | 3 | 2 | 0.76 | 0.57 | 14 | |

| 14 Efficacy of nematodes as biocontrol agents | 1 | 3 | 2 | 0.78 | 0.62 | 13 | |

| 10 Management of beet leafhopper | 1 | 3 | 1.92 | 0.62 | 0.38 | 13 | |

| 9 Management of cabbage whitefly in organic systems | 1 | 3 | 1.73 | 0.75 | 0.56 | 11 | |

| Priority | Least important | Neutral | Most important | Total | |||

| 1 Management of aphids including scouting, effective products or methods, spray timing | 0.00% | 0 | 14.29% | 2 | 85.71% | 12 | 14 |

| 2 Management of slugs (beyond Sluggo and mowing) | 21.43% | 3 | 35.71% | 5 | 42.86% | 6 | 14 |

| 3 Biological control of specific pests: which natural enemies are effective | 14.29% | 2 | 28.57% | 4 | 57.14% | 8 | 14 |

| 4 Metrics on measuring efficacy of biological control | 28.57% | 4 | 42.86% | 6 | 28.57% | 4 | 14 |

| 5 New or updated management of symphylans | 16.67% | 2 | 41.67% | 5 | 41.67% | 5 | 12 |

| 6 Resistance of aphids to current chemistries | 14.29% | 2 | 35.71% | 5 | 50.00% | 7 | 14 |

| 7 Longterm management of diamond back moth | 0.00% | 0 | 30.77% | 4 | 69.23% | 9 | 13 |

| 8 Resistance of diamond back moth to current chemistries | 7.69% | 1 | 30.77% | 4 | 61.54% | 8 | 13 |

| 9 Management of cabbage whitefly in organic systems | 45.45% | 5 | 36.36% | 4 | 18.18% | 2 | 11 |

| 10 Management of beet leafhopper | 23.08% | 3 | 61.54% | 8 | 15.38% | 2 | 13 |

| 11 Efficacy of organic insecticide chemistries | 18.18% | 2 | 18.18% | 2 | 63.64% | 7 | 11 |

| 12 General management of root maggot — chemical and nonchemical methods | 7.14% | 1 | 21.43% | 3 | 71.43% | 10 | 14 |

| 13 Management of flea beetles in organic and conventional systems | 7.69% | 1 | 15.38% | 2 | 76.92% | 10 | 13 |

| 14 Efficacy of nematodes as biocontrol agents | 30.77% | 4 | 38.46% | 5 | 30.77% | 4 | 13 |

| Q5: Are there any other IPM topics or problems that you would like to see researched? |

|---|

| RanMan on club root in turnip and rutabaga |

| No |

| Chemical controls of club root on brassicas |

| In general, soil-dwelling insect (including symphs) control |

| Q6: Regulatory issues: please rank the current importance of these regulatory topics to the PNW brassicas industry | |||||||

|---|---|---|---|---|---|---|---|

| Topic | Minimum | Maximum | Mean | Standard deviation | Variance | Count | |