Dave Stone, Food Innovation Center director and professor; Jovana Kovacevic, Extension food safety specialist and assistant professor; and Stephanie Brown, food safety specialist, all of the Food Innovation Center Agricultural Experiment Station and Oregon State University.

Introduction

In the world of food, cleaning and sanitation are critical to maintaining food quality and safety in your operation. Make cleaning and sanitizing programs part of your food safety culture. This culture starts at the top and permeates throughout your organization. Make sure those doing your cleaning and sanitizing are invested in safety, adequately trained, and supported in their work.

Process of cleaning and sanitizing surfaces

Your approach to cleaning and sanitizing will depend on whether your food-processing environment is wet, dry or a combination of both. This publication focuses on cleaning and sanitizing in a wet environment, where water is used to aid the cleaning process.

Cleaning and sanitizing in a wet processing environment is a four-step process involving:

- A prerinse

- Cleaning with detergent

- Rinse

- Application of a sanitizer

Most debris and some microorganisms are removed in the first three steps, allowing the sanitizer to effectively reduce remaining microorganisms to levels considered safe by public health agencies. You cannot sanitize a dirty surface. Furthermore, sanitizers are one tool that helps us to produce safe food. Sanitizers are not the final defense or a magic bullet. You must consider your entire production system to determine your food safety risks. Part of this process is deciding which sanitizers to use, frequency of sanitation, and verification of your sanitizing activities.

Here are some considerations and information for selecting and using sanitizers in the food industry.

Choosing a sanitizer

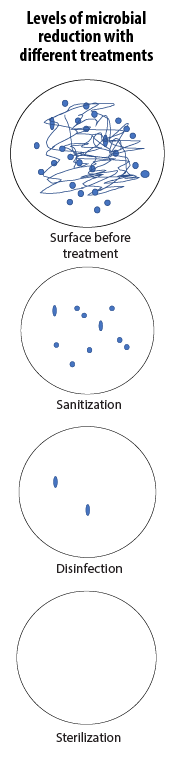

Once you have adequately cleaned a surface, you are ready to apply a sanitizer. Sanitizers, disinfectants and sterilant products are all classified as pesticides regulated by the Environmental Protection Agency. These products are registered to control bacteria, viruses or protozoans on environmental surfaces or inanimate objects. They are not registered for use on living surfaces, such as hands.

When applied correctly:

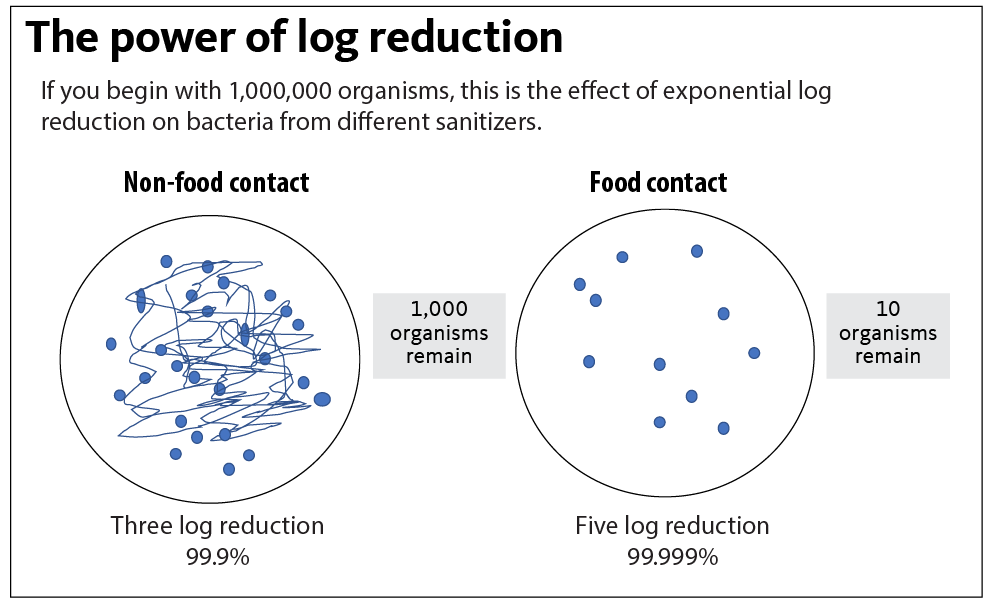

- Sanitizers destroy microorganisms down to levels that are considered unlikely to cause harm (typically a 5-log1 or 99.999% reduction on food contact surfaces). They can be applied to food contact surfaces and non-food contact surfaces, if permitted on the EPA product label.

- Disinfectants kill many or all pathogenic microorganisms except bacterial spores, which are a resistant life stage for some bacteria. These products are used on inanimate objects. They are commonly associated with healthcare settings and are not regularly used in the food industry.

- Sterilant products kill all forms of microbial life and are more common in healthcare and hospital settings.

Some products can be both a sanitizer and a disinfectant when used at different concentrations, on a different surface or with longer surface contact time.

Several databases will help you find the right product for your operation. For pesticide products registered in Oregon and Washington, visit the Pesticide Information Center OnLine (PICOL) database. For pesticide products registered in Idaho, visit the Idaho Department of Agriculture’s database of registered pesticides . For sanitizers labeled for use on fresh produce, refer to the Labeled Sanitizers for Produce – Excel Tool (Version 3.1) available at Produce Safety Alliance website.

You will likely be using sanitizers in your operation. Disinfectants may be used to control the spread of SARS-CoV-2, the virus that causes COVID-19.

Follow the label!

No matter what type of sanitizing or antimicrobial product you use, it is critical that you read the product label and follow the instructions. You have a legal responsibility to follow those instructions. If you have questions about the label, contact your state Department of Agriculture, land-grant university or the National Pesticide Information Center at 1 (800) 858-PEST.

Sections of a label

On the label, you will find:

- Active ingredients and concentration.

- Instructions for storage and disposal.

- Permitted surface types for application and microorganisms that are killed by the product.

- First aid information and any required personal protective equipment for users.

- Instructions for use, including dilution directions for concentrates, target concentration, contact time and whether rinsing is needed.

The EPA Registration Number listed on the label is the unique identifier for that product. If the label doesn’t have this number, the product might not be registered as a sanitizer or disinfectant in the U.S. Your state Department of Agriculture may have additional restrictions listed on the product label.

Bleach products are a good example of how the registration number and label information can assist you. Bleach is a commonly used disinfectant due to its efficacy against a wide range of microorganisms. A number of different bleach products are available in the U.S., and they may be intended for different applications. If a bleach product has an EPA registration number, it has been registered as a sanitizer or disinfectant (or both) with the agency.

The next step is to check the label to see if the product is suitable for use on food contact and non-food contact surfaces. This is extremely important. Some bleach products may have additives not intended for ingestion and cannot be used on food contact surfaces. An example would be scented or splash-free bleach. Additionally, recommended concentrations and contact time may be different for application on food contact surfaces compared to non-food contact surfaces. To avoid unintended uses, always check and follow the label!

Selection and purchasing considerations

When you are selecting and purchasing sanitizers, you will want to consider:

What are you sanitizing? Is it a food contact surface, such as a tabletop, or a non-food contact surface, such as table legs or a drain?

Products intended for use on food contact surfaces typically need to demonstrate a higher level of microbial load reductions (e.g., 5 log or 99.999%) compared to microbial reductions on non-food contact surfaces (e.g., 3 log or 99.9%). Also, target concentrations and contact time may be different for a sanitizer when it is applied to a food contact surface compared to a non-food contact surface.

Is your operation organic or conventional?

Synthetically derived sanitizers, such as the quaternary ammonium compounds (Quats), cannot be used on food contact surfaces in organic operations but may be used on non-food contact surfaces.

What type of surface or material are you sanitizing? Is it made of soft metals, porous or nonporous material?

Many sanitizing products are intended for use on nonporous surfaces only (e.g., stainless steel and plastic surfaces). Some materials can stain or corrode if certain sanitizers are used.

What personal protection equipment will you need to protect yourself or your workers when applying a particular sanitizer? Do you need barriers to protect from solid, liquid or airborne particles?

Depending on the product, different levels of protection equipment may be required. Consider what equipment is needed to provide appropriate barriers for your workers and how these will be used and disposed of.

Is the product in a ready-to-use form or does it need to be diluted?

Some products are available in a concentrated form and need to be diluted to achieve specific concentrations to be effective. Carefully follow the manufacturer’s instructions to calculate dilutions. Changing or diluting ready-to-use products may affect their efficacy.

What additional materials will you need to stock, label and store, such as buckets, spray bottles, wipes and utensils?

Some sanitizers must be stored in nonflammable or specific containers, away from other chemicals you may have in your facilities. If diluting sanitizers and transferring them outside the original container, make sure these containers or spray bottles have adequate labels, and that they are appropriately stored.

Types of sanitizers

There are several types of sanitizers, with pros and cons for each. Below are the three major sanitizer ingredients that are used for food contact surfaces. This is not a comprehensive list, and many other options exist, including iodine-based compounds for dipping utensils, chlorine dioxide for large operations and hydrogen peroxide. Information on different products can be found on the EPA’s Office of Pesticide Programs website.

|

Type of sanitizer |

Important considerations |

|

Hypochlorous acid Otherwise known as sodium hypochlorite (liquid bleach) or calcium hypochlorite (powder or briquette), hypochlorous acid is a common and relatively inexpensive sanitizer with a broad spectrum of killing different microorganisms. The availability of free chlorine (as opposed to total chlorine) is what kills the microorganisms. |

|

|

Peroxyacetic acid (PAA) PAA is a common active ingredient in sanitizers used in the food industry, with broad-spectrum killing capabilities and typically considered to be more environmentally friendly when compared to other sanitizers. |

|

|

Quaternary ammonium compounds (Quats) Commonly referred to as Quats, these are synthetic, complex mixtures of large compounds. They are cationic surfactants that impact bacterial cell membranes and the lipids in viruses. |

|

Important considerations when using sanitizers

- More is not better. Read the label and use the appropriate concentration listed for the correct contact time.

- Do not combine different active ingredients unless directed to do so on the label. Several dangerous medical outcomes have resulted when different products are mixed together. Mixing bleach with ammonia-containing compounds, vinegar or rubbing alcohol produces poisonous chlorine gas, which has resulted in worker deaths.

- If you must use another container than the original labeled product, label it with the active ingredient and store it appropriately, preferably in a locked storage cabinet.

- Be sure to have adequate personal protection equipment on hand and remember to regularly check and restock your first-aid kits and equipment. Lotions, creams and eye wash solutions expire and need to be replaced.

- Sanitizers are not a substitute for good hygiene practices, such as washing hands, nor are they an excuse to be lax on adherence to good manufacturing practices.

- Be mindful of whom you assign to perform your cleaning and sanitizing procedures. Whether it is you or someone else, this person or team needs to have the proper training, effective communication and organization skills, and overall dedication to food safety culture.

Resources

Pesticide Information Center OnLine (PICOL) database. Accessed August 17, 2020.

Idaho State Department of Agriculture. Database of registered pesticides. Accessed August 31, 2020.

Produce Safety Alliance. Labeled Sanitizers for Produce – Excel Tool (Version 3.1).

CDC. Coronavirus (COVID-19). Get the facts about coronavirus. Accessed July 9, 2020.

EPA. Pesticide registration. List N: Disinfectants for use against SARS-CoV-2 (COVID-19). Accessed July 9, 2020.

EPA. News releases. EPA approves first surface disinfectant products tested on the SARS-CoV-2 virus. Accessed July 9, 2020.

EPA. Coronavirus (COVID-19). Accessed July 9, 2020.

EPA. Pesticides. Accessed July 9, 2020.

FDA. Food safety and the coronavirus disease 2019 (COVID-19). Accessed July 9, 2020.

1 Log reduction measures how much a decontamination process reduces the concentration of a microbiological contaminant. A 1-log reduction is a 90 percent reduction or achieving a 10 times lower number of microorganisms, and a 5-log reduction is a 99.999% reduction or achieving a 100,000 times lower number of microorganisms.

Products for SARS-CoV-2

While SARS-CoV-2 is not a foodborne virus and it has not been identified as a food safety issue, it has led to many outbreaks in food handling and processing operations. Inactivation of virus particles is an important strategy to prevent viral spread among workers.

The EPA established guidance for Emerging Viral Pathogens, including a list of products that meet the agency’s criteria for use against SARS-CoV-2, known as “List N.”

Recently, the EPA approved two surface disinfectant products (Lysol Disinfectant Spray, EPA Reg No. 777-99; and Lysol Disinfectant Max Cover Mist, EPA Reg No. 777-127) that have been tested directly against the SARS-CoV-2 on hard, nonporous surfaces.

Of these two products, only the Lysol Disinfectant Spray (EPA Reg No. 777-99) is labeled for use on food contact surfaces. However, when applied to a food contact surface, a post-rinse is required. As COVID-19 is an ongoing and rapidly evolving situation, for the most current information, please refer to the Centers for Disease Control and Prevention, EPA, and FDA websites.

© 2020 Oregon State University.