Your customers trust that the farm-direct food they buy from you is safe, and you must work to live up to that trust. A food safety incident will result in major problems for your farm: legal liability, regulatory liability, loss of customers and their trust, and the heartbreak of knowing that you may have been responsible for a foodborne illness.

If you are selling your own farm-fresh produce directly from your farm or on a small scale at a local farmers market, there may not be many regulations that apply to your business. However, you will still want to follow guidelines to keep your foods fresh and safe and to trace your product to market in case of an outbreak of foodborne illness. This publication reviews basic food safety techniques and guidelines.

If you are selling higher-risk foods such as animal products, or if you do any food processing, then you may be required to comply with state or federal regulations, licenses, and inspections. New food safety laws may include more of your on-farm operations under the definition of “processing,” which means that, from a regulatory standpoint, more precautionary steps may be necessary. For more information, see Legal Guide to Farm-direct Marketing (PNW 680). Laws and regulations change frequently, so keeping up on the food safety requirements and regulations for specific foods is an important part of your job as a farm-direct marketer.

If you check with your state department of agriculture and find that you do not need a license for your farm-direct sales, you may still want to seek voluntary certification to show that you are following food safety guidelines. This may help to build customer confidence. Voluntary certification of Good Agricultural Practices (GAPs) and Good Handling Practices (GHPs) are available through your state department of agriculture or through USDA. Many universities also provide GAPs assistance and classes for small enterprises. GAPs certification may be required if you are selling to retail, restaurants, or institutions, or possibly to other kinds of buyers. It also gives you some peace of mind to check in periodically with your food safety procedures and know that you are staying up to date.

Washington State Department of Agriculture, Food Safety Program http://agr.wa.gov/FoodAnimal/FSP/

Oregon Department of Agriculture, Food Safety Program http://www.oregon.gov/ODA/programs/FoodSafety/Pages/Default.aspx

Idaho Department of Agriculture, Food Safety Program http://www.agri.idaho.gov/Categories/InspectionsExams/FoodSafety/indexf…

Keeping Your Products Fresh and Safe

• Moisture loss

• Rough handling

• Decay and rot

• Chilling and freezing

• Proper storage

• Sanitation

• Inventory control

• Customer handling

Respiration

Plant respiration takes in oxygen, combines it with plant sugars through enzymatic action, and gives off carbon dioxide and heat. Each type of fruit and vegetable has its own respiration rate. For instance, respiration is faster in fresh peas, corn, and berries than in potatoes, apples, and cabbage. The most perishable commodities have the highest respiration rates and the least perishable have the lowest. Thus, in fruit and vegetable marketing, the “fast living” commodities (high respiration rates) cause the greatest handling problems and quality losses.

Most fruits and vegetables are 80 to 95 percent water. In dry air, they wilt and shrivel; in refrigerated dry air, they shrivel severely. Low temperatures slow respiration rates, but to prevent moisture loss, you must control humidity in storage. The two should always be tied together: refrigeration and high humidity.

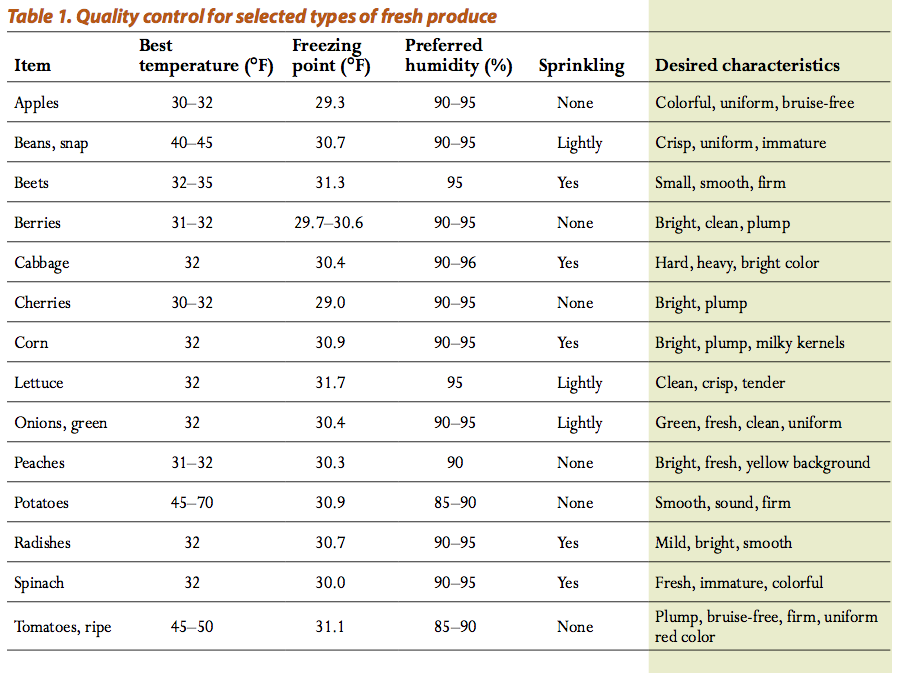

Refrigerated storage with a relative humidity of 85 to 95 percent is recommended. You can add sufficient moisture (humidity) to a storage area in a number of ways. Fine sprays, fans blowing through wet burlap or other material, evaporation pans, or commercial humidifiers are a few suggestions. See Table 1, for specific refrigeration and humidity requirements.

The principle to follow: Remove the field heat as soon as possible after harvest, and use refrigeration and high air humidity to maintain quality and reduce losses.

Rough handling

Rough handling causes crushing, cuts, and bruises that affect the visual appeal of all soft fruits and vegetables. Bruises show up almost immediately on apples, peaches, light cherries, eggplant, cucumbers, pears, and tomatoes. Sweet corn, potatoes, cauliflower, plums, prunes, and some others may not show signs of bruising until the customer takes them home and starts preparing them—and that’s bad for your image.

Careful handling is a must to prevent damage. Do not dump perishable items into displays. Instead, roll or slide them carefully from their field containers or handle them individually. Make sure not to stack items too high to avoid bruising or crushing. Also, do not throw or drop boxes; set them down without jarring them. Avoid having sharp edges on a display that could cause damage to the produce.

Decay and rot

Rough handling increases losses from decay and rot. All fruits and vegetables are covered with microorganisms such as bacteria and mold spores, some of which can cause decay when the conditions are right. The best way to reduce rot is to remove field heat quickly and remove as much dirt as possible from the produce prior to storage. Most microorganisms grow rapidly at warm temperatures, so refrigeration is also good for controlling decay by slowing it down.

Rough handling that causes cuts or bruises the fruit or vegetable’s skin allows microorganisms to enter internal tissues and damage the food. Injured areas allow microbes to enter the tissue that provides them with the nutrients and water they need for growth. Even though refrigeration slows microbe growth, it does not stop it, and produce will continue to rot during refrigeration. This is particularly true for soft fruits such as peaches.

It is also important to know the cold sensitivity of your produce because chill injury also causes loss of quality. Chill injury can cause tissue damage that allows microbes to enter the product and grow.

Research has shown that some dips and gases successfully retard decay. Still, farm-direct businesses rely most heavily on refrigeration and careful handling to prevent bruising and skin punctures that lead to decay and rot.

Chilling and freezing

Many fruits and vegetables cannot withstand low temperatures; in fact, holding temperatures that are too low can damage them. Some produce, such as green tomatoes, may not ripen after chilling, or may ripen with a blotchy or dull appearance or turn brown. The poor appearance might force you to discount the price or discard the item.

As Table 1 shows, ideal chilling temperatures differ for different fruits and vegetables. Those that need less chilling (are more susceptible to chill injury) include snap beans, acorn squash, eggplant, cucumbers, peppers, tomatoes, and citrus fruits. Potatoes, sweet potatoes, and winter squash are best held around 45°F or 50°F and should be kept in a dry place; very high humidity is their enemy. Some fruits and vegetables, because of their high sugar content, can withstand temperatures below 32°F, but not too much lower and not for an extended time. The item will freeze and sustain irreparable cell damage.

Proper storage

Storage does not have to be elaborate. Storage facilities can range from a hole in the ground to large walk-in coolers with completely automated controls. What is important is to keep the area clean and at the right temperature and humidity.

Use a type of storage that is suited to your business and its size. If you are selling only a few items from a bench or table in the front yard, perhaps a hole in the ground (lined, if possible, to avoid contamination) covered with clean, wet burlap is all you need—or perhaps a standard root cellar on your farm is enough. On the other hand, if you plan to handle a large volume of perishables, then a walk-in cooler with humidity control is necessary. Some operators rent or buy a refrigerated box from a trucking company or salvage yard. You can place it near the rear entrance of your farm stand or market, and you will have an ideal walk-in cooler.

Precooling

Precooling fruits and vegetables before placing them in storage can reduce refrigeration needs and extend storage life by several days or weeks. Local refrigeration engineers or university Extension specialists may be of great help as you plan this critical part of your enterprise. The main thing to remember is to remove the heat prior to storage, with no greater than a 10°F change in temperature during the initial cooling phase, while handling the product as gently as possible.

Practical ways to precool include:

• Rapidly moving cold or moist air

• Hydocooling

• Contact ice or top ice

Hydrocooling either floods or immerses the product in cold water. Hydrocoolers do not have to be elaborate. An old bathtub, one-third full of water plus enough ice to chill the water, works fine. Immerse fruits or vegetables for 15 to 20 minutes, or long enough to reduce the temperature to a point within the ideal range (see Table 1 and “Chilling and freezing”). Items with a high surface area (such as greens, beans, and asparagus) require a shorter immersion time. Likewise, items with a low surface area (such as large apples, stone fruits, or melons) require a longer immersion time. Generally, items picked during a hot time of day require a longer immersion time to reduce the temperature to the ideal range.

You can make a more sophisticated hydrocooler by building a tunnel over an old grading table. In the tunnel, arrange a series of pipes with spray nozzles, and put a conveyor belt on top of the grading table. Gear the belt to move slowly. As a crate of fruit or vegetables moves through the tunnel on the belt, potable re-circulated water or ice water sprays over the items to carry away heat.

Water can spread any microbes present on an item or in the water itself. Make sure to use potable water in the hydrocooling process. You may use an approved sanitizer to disinfect the water and reduce the risk of spreading any contamination. Check with your local university Extension Service office for advice.

Storing mixed commodities

Haphazardly mixing fruits and vegetables in storage can reduce produce quality. Some products absorb odors from others. Some give off volatile compounds, such as ethylene, that harm other types of produce.

Guidelines for storing mixed produce include:

• Deciduous fruits (apples, pears, peaches, plums, etc.) can generally be stored together if they have the same humidity and temperature requirements.

• Do not store apples and peas with celery, cabbage, carrots, potatoes, or onions.

• Lettuce and carrots are damaged when stored with apples, pears, and many other fruits that give off ethylene gas.

• Do not store cucumbers, peppers, or acorn squash—whose green color you want to retain—with apples, pears, tomatoes, or other ethylene-producing products.

• Meat, eggs, and dairy products readily absorb odors from apples and citrus fruits. Therefore, keep these items separated from fruit.

For more information, contact your local Extension agent, university experiment station, or the produce manager in a local supermarket. If other farm-direct sellers are willing to provide guidance, it’s a good sign that the market for your planned products is open in your area. The library and Internet may provide produce-handling guides and other possible sources of information.

Sanitation

Sanitation is almost always a problem. Fruits and vegetables are extremely susceptible to many microorganisms, including spoilage bacteria and mold spores in the air or in the soil. Refrigeration does not kill bacteria, it only slows their growth, so refrigeration is not an alternative to good sanitation. The only reliable way to kill microbes that might be present is to heat the food, but much of the produce farmers sell is ready to eat and will not be heated before it is eaten.

Even with the best washing and sanitation practices, it is not possible to remove all of the bacteria from the surface of fruits and vegetables. However, it is possible to reduce the number of microorganisms and to prevent further contamination. Thus, one of your major responsibilities is to frequently wash and disinfect carriers, tubs and totes, cutting knives, display racks, storage areas, scales, and other items that come into contact with the produce and could become contaminated.

Protect food from insects and rodents because they are sources of harmful bacteria. Personnel hygiene is also critical. Some of the most common causes of foodborne illness are people failing to wash their hands after using the toilet and spreading viruses or bacteria by sneezing or coughing around the food.

6Store any chemicals, including detergents, sanitizers and insect sprays, away from the food. Make sure that the primary container and any secondary container (such as a spray bottle for water, bleach, or hand sanitizer) are prominently labeled so that no one makes a mistake using them. We recommend that you store any chemicals at your display site in a separate, covered container and not in the same container as food packaging, paper toweling, or other such products, to limit the risk of contaminating the food.

Only have the quantity of chemicals on site that you might need for the day. Make sure that any chemicals you purchase are appropriate for their intended use. For example, do not use bleach with color or fragrance on food or on food contact surfaces. If you have questions about what is appropriate, check with your vendor or contact your university Extension office for advice.

Inventory control

Inventory control is another major factor in maintaining fruit and vegetable quality. An important step is to harvest when your products reach optimum maturity. Until then, store them in the field or on the tree. Bring to the sales area only the volume needed to maintain attractive displays and satisfy demand during a specific period. Those periods will change in length as seasonal temperatures vary.

When you restock a display, remove the old products, add the new, and put the old on top of the new and near the front. Rotating the stock this way can help retain quality. When replenishing a display, some operators move all older items to a markdown counter and put only fresh items on the display rack. This is a good merchandising technique because it maintains good eye appeal for higher-priced items on display.

Customer handling

Some marketers think their responsibility for product quality ends when customers leave the stand. This attitude is dangerous because it is inconsistent with the need for repeat business, which is important for financial success.

If customers mishandle produce after they’ve bought it, they may believe you are responsible for its reduced quality. As you talk to your customers about the high quality of the products they are buying, you can also offer storage and handling suggestions to maintain that quality. In addition, you can supply leaflets that suggest best ways to handle, store, and use the items.

Fresh, flavorful products are why customers buy from you in the first place. Many need help not only to buy but also to maintain that quality until the item reaches the table.

For More Information

“Farmers’ Guide to Reducing the Legal Risks of a Food Safety Incident.” 2014. Farm Commons. http://farmcommons.org/resources/farmers-guide-reducing-legal-risks-foo…

Keeping it Legal: Regulations and Licenses for Growing and Selling Food in Oregon. 2014. OSU Small Farms Program. http://smallfarms.oregonstate.edu/sites/default/files/regs_licenses_han…

The Farm-direct Marketing Set

A farm-direct marketing business provides both attractive opportunities and unique challenges to farm families. The farm-direct marketing series of Extension publications offers information about establishing and developing a range of farm-direct enterprises.

Other publications in the series are:

• An Overview and Introduction (PNW 201)

• Costs and Enterprise Selection (PNW 202)

• Merchandising and Pricing Strategies (PNW 203)

• Location and Facilities for On-farm Sales (PNW 204)

• Personnel Management (PNW 205)

• Financial Management (PNW 206)

• Legal Guide to Farm-direct Marketing (PNW 680)

To learn more, consider one of the online courses offered by Oregon State University, Washington State University, and University of Idaho:

In Oregon—Growing Farms: Successful Whole Farm Management https://pace.oregonstate.edu/catalog/growing-farms-successful-whole-far…

In Washington—Cultivating Success™ Sustainable Small Farms Education Program: http://cultivatingsuccess.wsu.edu

In Idaho—Cultivating Success™ Sustainable Small Farms Education Program: www.cultivatingsuccess.org

This information is provided for educational purposes only. If you need legal [or tax] advice, please consult a qualified legal [or tax] adviser.

Trade-name products and services are mentioned as illustrations only. This does not mean that the Oregon State University Extension Service either endorses these products and services or intends to discriminate against products and services not mentioned.

Use pesticides safely!

- Wear protective clothing and safety devices as recommended on the label. Bathe or shower after each use.

- Read the pesticide label—even if you’ve used the pesticide before. Follow closely the instructions on the label (and any other directions you have).

- Be cautious when you apply pesticides. Know your legal responsibility as a pesticide applicator. You may be liable for injury or damage resulting from pesticide use.

© 2018 Oregon State University.

Extension work is a cooperative program of Oregon State University, the U.S. Department of Agriculture, and Oregon counties. Oregon State University Extension Service offers educational programs, activities, and materials without discrimination on the basis of race, color, national origin, religion, sex, gender identity (including gender expression), sexual orientation, disability, age, marital status, familial/parental status, income derived from a public assistance program, political beliefs, genetic information, veteran’s status, reprisal or retaliation for prior civil rights activity. (Not all prohibited bases apply to all programs.) Oregon State University Extension Service is an AA/EOE/Veterans/Disabled.

Growing Farms Online Course: Learn how to start a successful sustainable small farm.

Developed by OSU Small Farms Program faculty and other farm management experts, you will learn the essentials of designing and growing your own thriving farm business. And the entire program is available online, so you can complete it on your time, around your schedule. Turn your dream of owning and operating a small farm or ranch into a successful reality with this popular program!