After several months of taking care of your hemp plants in the field, harvest season is in full effect.

This is when the hemp flowers (buds) are plump and ready to be processed into their final product. The profitability of hemp growers and the creation of reliable, consumable hemp-derived products such as CBD depend on the final quality of the flowers.

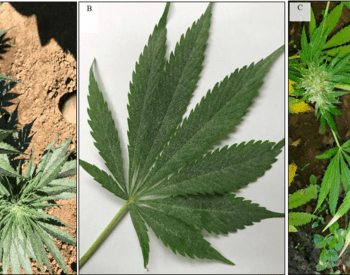

Fresh hemp tissues (containing 70–80% water) are trimmed, dried, cured and stored prior to selling the flowers for compound extraction or as smokable flowers (figure 1). This is a brief review of post-harvest practices and how it can impact the flower’s quality.

Choosing the right time to harvest can affect biochemical concentration before harvesting. Research has shown that the color of trichomes (the structure that houses cannabinoids and terpenes) changes throughout the growing period from clear to milky to amber. This can potentially indicate the best time to harvest based on the end use of the plant and desired chemical composition.

Moving into the post-harvest process, trimming requires the removal of the plant parts, which include fan leaves, stems and roots. The remaining parts of the plant are buds with sugar leaves. Whether to trim these small leaves before (wet trimming) or after drying (dry trimming) is up to the producer. This process can be done manually using shears or automatically using equipment. Just be sure to consider which trimming method will ease the flow of operations and what process preserves the structure of the trichomes on the hemp flower.

Effectively reducing the product’s moisture content causes a decrease in unwanted microbial growth and minimizes the likelihood of deterioration during storage. The most commonly practiced drying method is “slow drying," which allows the flowers to be dried in a dark room with fans, dehumidifiers, or heaters. However, inadequate control of environmental conditions (relative humidity and temperature) can lead to long drying times and poor-quality flowers.

Modern technology such as convection, infrared and freeze drying are viable solutions for decreasing drying times and preserving quality. At the same time, some of these technologies require capital, infrastructure for the equipment and maintenance, and can potentially consume a lot of energy. When using the slow-drying method, ensure the room is well-ventilated, the temperature is 18–21 °C and relative humidity is 50–55%. This process can be done in a simple structure like a barn or shipping container.

Hemp is "cured" to improve the quality and flavor of hemp flowers by allowing the chemical composition to develop over a period of time. It signals the conclusion of drying and the start of storage, during which the hemp flowers are kept at the appropriate moisture content (55–65%) and water activity levels (<0.65). To maintain the quality of hemp, it is crucial to do this action.

Even though curing is one of the most important post-harvest processes, it is not yet extensively explored in research. One study says that before calculating the dry flower weight, the dried material should be cured at 18°C and 60% RH for 14 days. To acquire the optimum product for storage and marketing, additional research should be done on how time, temperature, humidity, and packaging affect the quality during curing.

Lastly, improper storage conditions will contribute to the degradation of hemp flowers and their biochemical compounds. Research has shown that storing flowers in the presence of light, exposure to air and high temperature can negatively affect some cannabinoid concentrations. Therefore, if the flower is being dried long-term, it is suggested to store the manicured buds in a cold, dry place at a temperature of 18°C and RH between 45–55%.

Overall, research has to catch up to what the industry is currently doing. More studies can help improve current post-harvest processes. Adopting accessible post-harvest practices that ensure consistently safe and high-quality hemp flowers is of the utmost importance for farmers and consumers. Wishing you pounds of well-manicured, green, slightly sticky, cannabinoid and terpene-dense buds this season!